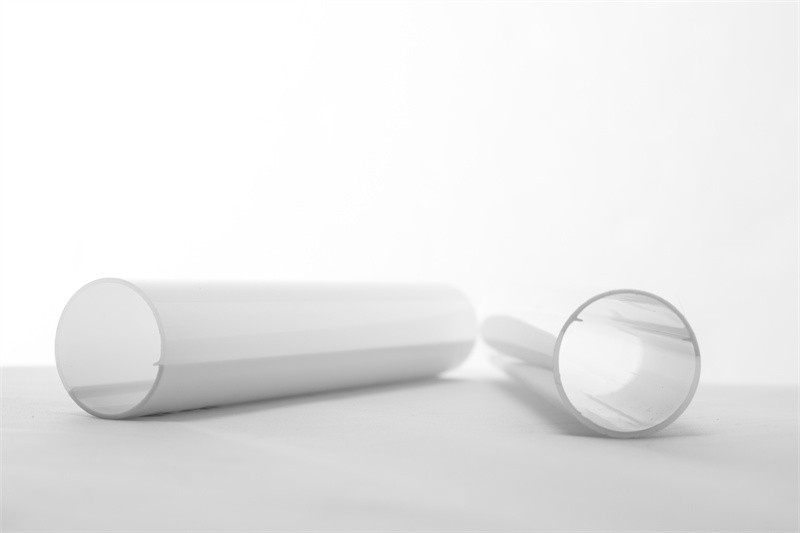

low medium viscosity high clarity easy release polycarbonate resins for lighting lens optical

low medium viscosity high clarity easy release Polycarbonate (PC)"FOREVER" granuels or pellets are widely used in the applications of lighting lens optical fields

Polycarbonate (PC)"FOREVER" granuels or pellets, low medium viscosity high clarity easy release,

F1,Suitable for outdoor use with respect to exposure to Ultraviolet Light,

Water Exposure and Immersion in accordance with UL 746C.

The applications are lighting, lens or optical fields

Product Description | |||

MVR (300°C/1.2 kg) 34 cm³/10 min; light guides; optics and lenses; PC with highest transmission; low viscosity; easy release; injection molding - melt temperature 280 - 320°C | |||

General | |||

Form |

| ||

Feature |

|

| |

Uses | |||

Physical | Nominal Value | Test Method | |

Density / Specific Gravity(23 °C) | 1.20g/cm³ | ISO 1183 | |

Melt Volume-Flow Rate, MVR(300 °C;1.2 kg) | 34 cm³/10 min | ISO 1133 | |

Ball Indentation Hardness | 115 MPa | ISO 2039-1 | |

Mechanical Nominal Value | Test Method | |

Tensile Modulus(23 °C) 2350 MPa | ISO 527-2/1 | |

Tensile Strain, Break(23 °C) 130 % | ISO 527-2/50 | |

Nominal Tensile Strain at Break(23 °C) > 50 % | ISO 527-2/50 | |

Flexural Modulus(2 mm/min;23 °C) 2350 MPa | ISO 178 | |

Flexural Stress 2 mm/min;23 °C 2 mm/min;3.5% Strain;23 °C |

97.0 MPa 73.0 MPa | ISO 178 |

Flexural Strain at Flexural Strength(2 mm/min;23 °C) 7.1 % | ISO 178 | |

C harpy Notched Impact Strength, Complete Break(-30 °C;3 mm) | 12 kJ/m² | ISO 179 1eA |

C harpy Notched Impact Strength, Partial Break(23 °C;3 mm) | 60 kJ/m² | ISO 179 1eA |

C harpy Unnotched Impact Strength -60 °C -30 °C 23 °C |

No Break No Break No Break | ISO 179 1eU |

Notched Izod Impact Strength, Complete Break(-30 °C;3 12 kJ/m² mm) | ISO 180/1A | |

Notched Izod Impact Strength, Partial Break(23 °C;3 mm)55 kJ/m² | ISO 180/1A | |

Multi-Axial Instrumented Impact Energy -30 °C 23 °C |

60.0 J 55.0 J | ISO 6603-2 |

Multi-Axial Instrumented Impact, Peak Force -30 °C 23 °C |

5900 N 4900 N | ISO 6603-2 |

Thermal | Nominal Value | Test Method |

Heat Deflection Temperature, Unannealed 0.45 MPa 1.8 MPa |

138 °C 125 °C |

ISO 75-2/B ISO 75-2/A |

Glass Transition Temperature(10 °C;min) | 145 °C | ISO 11357-2 |

Vicat Softening Temperature |

145 °C 146 °C |

ISO 306/B50 ISO 306/B120 |

| <

Previous:High Modulus Flame Retardance UV Stabilized PC Polycarbonate

Next:Rubber Raw Material Polypropylene Plastic Raw Material PA6 Particle Native Polycarbonate Resin

Inquiry |