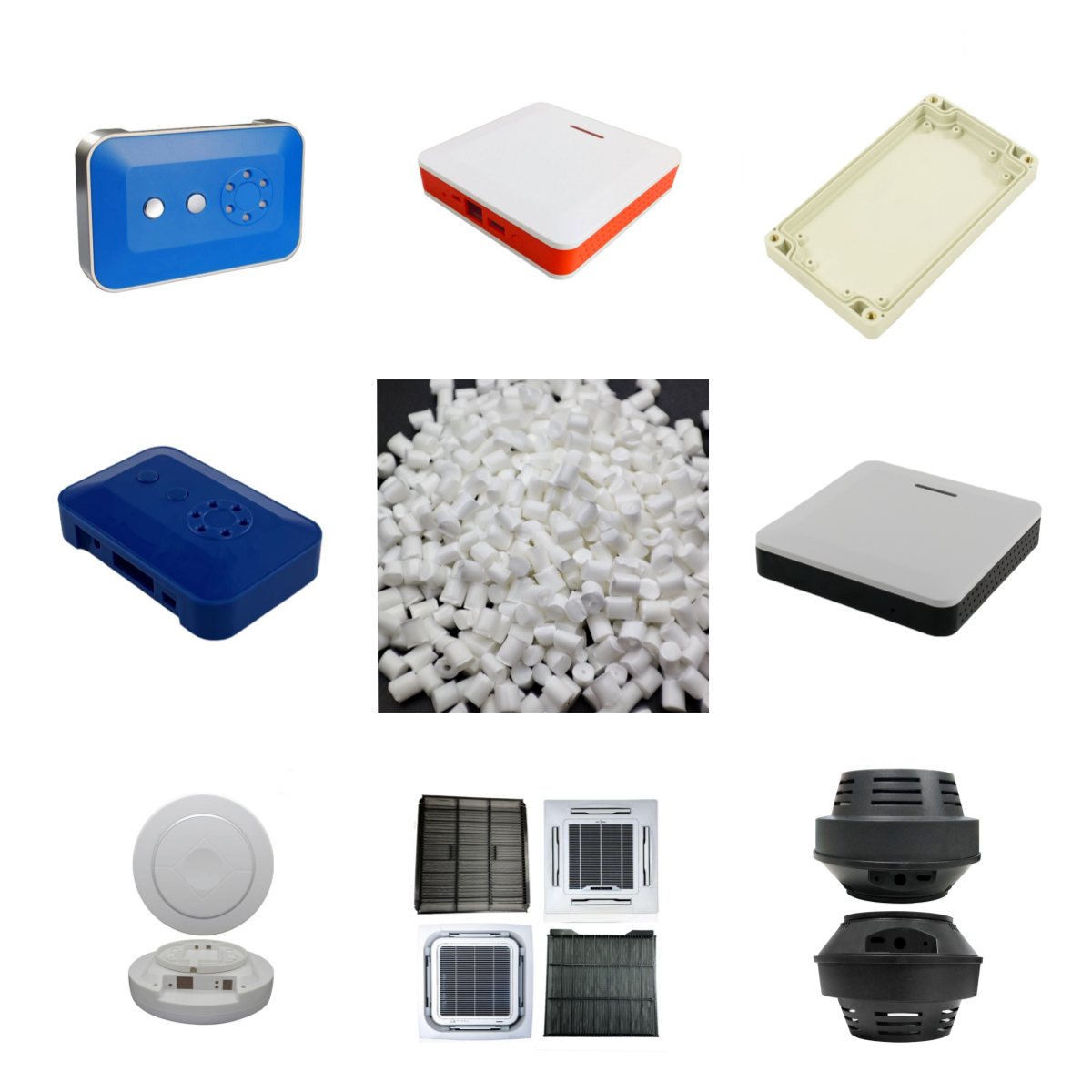

Non-filled, Injection Moldable Grade Polycarbonate (PC) Resin

Dongguan Forever Co.,Ltd is the manufacture of the China origin cheap UV stablized PC polycarbonate Granules Polymer Resin

LUX7430C-XH is a type of Polycarbonate (PC) resin that can be easily molded through injection.This non-chlorinated, non- brominated flame retardant PC has an UL-94 V0 rating at 1.2 mm / 5VA rating at 3.0mm and is UV stabilized(F1 rating) providing additional weathering capability. Additionally, this resin has been UV stabilized with an F1 rating, making it more resistant to weathering. LUX7430C is offered in both clear transparent and tinted color options, making it suitable for a diverse range of applications.

General | ||||

Form |

| |||

Feature |

| Non-Brominated & Non- Chlorinated Flame Retardant | Non-Chlorinated | |

Usage |

|

|

| |

Physical | Nominal Value | Test Method | ||

Density / Specific Gravity | 1.19 1.2 g/cm³ | ASTM D792 ISO 1183 | ||

Melt Flow Rate[MFR](300 °C;1.2 kgf) | 10 g/10min | ASTM D1238 | ||

Water Absorption(23 °C;saturated) | 0.13 % | ISO 62-1 | ||

Moisture Absorption(50% RH;23 °C) | 0.1 % | ISO 62 | ||

Melt Volume Rate, MVR(1.2 kg;MVR at 300 °C) | 9 cm³/10 min | ISO 1133 | ||

UV light, water exposure/immersion | f1 | UL 746C | ||

Mechanical | Nominal Value | Test Method | ||

Izod Impact, Unnotched | ASTM D4812 | |||

23 °C | NB J/m | |||

-30 °C | NB J/m | |||

Izod Impact, Notched | ASTM D256 | |||

23 °C | 100 J/m | |||

-30 °C | 81 J/m | |||

Instrumented Dart Impact, Total Energy(23 °C) | 64 J | ASTM D3763 | ||

Unnotched Izod Impact Strength unnotched;80*10*3;23 °C 0 unnotched;80*10*3;-30 °C 0 | NB kJ/m² NB kJ/m² | ISO 180/1U |

Notched Izod Impact Strength notched;80*10*3;23 °C 0 notched;80*10*3;-30 °C 0 | 9 kJ/m² 8 kJ/m² | ISO 180/1A |

C harpy Impact, V-Notched 23 °C;Edgew;80*10*3;sp =62mm 0 -30 °C;Edgew;80*10*3;sp =62mm 0 | 10 kJ/m² 7 kJ/m² | ISO 179 1eA |

C harpy Impact, Unnotched 23 °C;Edgew;80*10*3;sp =62mm 0 -30 °C;Edgew;80*10*3;sp =62mm 0 | NB kJ/m² NB kJ/m² | ISO 179 1eU |

Tensile Stress, Yield | ||

50 mm/min;Type I | 67 MPa | ASTM D638 |

50 mm/min | 66 MPa | ISO 527 |

Tensile Stress, Break | ||

50 mm/min;Type I | 55 MPa | ASTM D638 |

50 mm/min | 53 MPa | ISO 527 |

Tensile Strain, Yield | ||

50 mm/min;Type I | 6 % | ASTM D638 |

50 mm/min | 6 % | ISO 527 |

Tensile Strain, Break | ||

50 mm/min;Type I | 55 % | ASTM D638 |

50 mm/min | 56 % | ISO 527 |

Tensile Modulus | ||

50 mm/min | 2520 MPa | ASTM D638 |

1 mm/min | 2350 MPa | ISO 527 |

Flexural Stress, Yield | ||

1.3 mm/min;50 mm;span | 107 MPa | ASTM D790 |

2 mm/min | 101 MPa | ISO 178 |

Flexural Modulus | ||

1.3 mm/min;50 mm;span | 2450 MPa | ASTM D790 |

2 mm/min | 2450 MPa | ISO 178 |

Thermal | Nominal Value | Test Method |

UL Recognized ≥ 3 mm ≥ 1.2 mm ≥ 1 mm ≥ 0.4 mm | 5VA V-0 V-1 V-2 | UL 94 |

Glow Wire Ignition Temperature [GWIT] 3 mm 1.2 mm | 850 °C 850 °C | IEC 60695-2-13 |

Glow Wire Flammability Index 3 mm 1.2 mm | 960 °C 960 °C | IEC 60695-2-12 |

Vicat Softening Temperature Rate B/50 Rate B/50 Rate B/120 | 136 °C 137 °C 139 °C | ASTM D1525 ISO 306 ISO 306 |

Heat Deflection Temperature[HDT], Unannealed 0.45 MPa;3.2 mm 3.2 mm;1.82 MPa | 131 °C 120 °C | ASTM D648 |

CTE, Flow -40 - 40 °C 23°C to 80°C | 6.7e-05 1/°C 7.7e-05 1/°C | ASTM E831 ISO 11359-2 |

CTE, XFlow -40 - 40 °C 23°C to 80°C | 6.7e-05 1/°C 7.9e-05 1/°C | ASTM E831 ISO 11359-2 |

Ball Pressure Test(125°C +/- 2°C) | Pass | IEC 60695-10-2 |

HDT/Be(Edgew;120*10*4;sp =100mm; 0.45 Mpa) | 131 °C | ISO 75/Be |

Hdt/Ae(1.8 MPa;Edgew;120*10*4;sp =100mm) | 120 °C | ISO 75/Ae |

Relative Temp Index, Elec | 125 °C | UL 746B |

Relative Temp Index, Mechanical with Impact | 120 °C | UL 746B |

Relative Temp Index, Mechanical without Impact | 125 °C | UL 746B |

Electrical | Nominal Value | Test Method |

Dielectric Constant, Dk(1.1e+9 Hz) | 2.79 | ASTM ES 7-83 |

Dissipation Factor, Df(1.1e+9 Hz) | 5.7E-03 | ASTM ES 7-83 |

Comparative Tracking Index, CTI | PLC 3 | UL 746A |

Hot-wire Ignition, HWI ≥ 3 mm ≥ 1.2 mm | PLC 0 PLC 3 | UL 746A |

High Amp Arc Ignition, HAI( ≥ 1.2 mm) | PLC 0 | UL 746A |

Optical | Nominal Value | Test Method |

Light Transmission(2.54 mm) | > 91 % | ASTM D1003 |

Processing | Nominal Value | |

Drying Temperature<Injection> | 120 °C | |

Drying Time<Injection> | 3 - 4 hrs | |

Drying Time, Cumulative<Injection> | 48 hrs | |

Maximum Moisture Content<Injection> | 0.02 % | |

Melt Temperature<Injection> | 280 - 305 °C | |

Nozzle Temperature<Injection> | 275 - 300 °C | |

Front, Zone 3 Temperature<Injection> | 280 - 305 °C | |

Middle, Zone 2 Temperature<Injection> | 270 - 295 °C | |

Rear, Zone 1 Temperature<Injection> | 260 - 280 °C | |

Mold Temperature<Injection> | 70 - 95 °C | |

Back Pressure<Injection> | 0.3 - 0.7 MPa | |

Screw Speed <Injection> | 40 - 70 rpm | |

Shot To Cylinder Size<Injection> | 40 - 60 % | |

Vent Depth <Injection> | 0.025 - 0.076 mm |

Resin Pellets

Resin Pellets