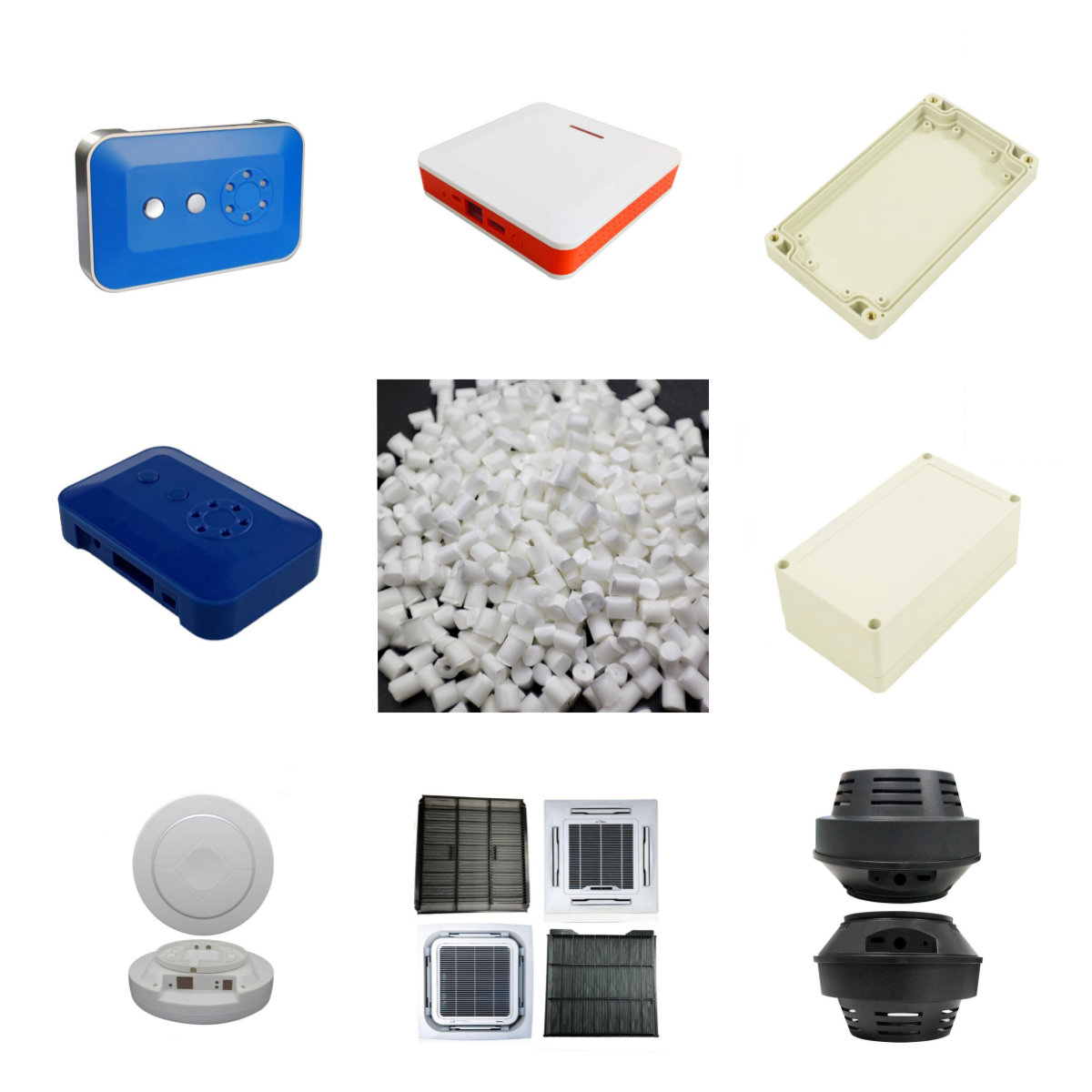

Recycled Polycarbonate (PC) Resin with High Modulus, Low Warpage, And Good Ductility of Glass Fibers

Dongguan Forever Co.,Ltd is the manufacture of the China origin cheap UV stablized PC polycarbonate Granules Polymer Resin

D251RC-XH compound is a type of recycled Polycarbonate (PC) resin that includes 20% glass fiber. This grade offers several benefits such as high stiffness, minimal distortion, good flexibility, and is free from bromine and chlorine-based flame retardants. Additionally, it contains up to 35% of post-consumer recycled Polycarbonate material.

General | |||||

Form | Resin Pellets | ||||

Filler | 20 % Glass Fiber | ||||

Feature | 35 % Pcr Pcr |

Non-Brominated & Non- Chlorinated Flame Retardant

| Good Hardness Non-Chlorinated Structural Enhanced Ductility | ||

Usage | Consumer | Electrical |

| ||

Physical | Nominal Value | Test Method | |||

Melt Flow Rate[MFR] 300 °C;1.2 kgf 300 °C;2.16 kgf | 12 g/10min 25 g/10min | ASTM D1238 | |||

Density / Specific Gravity | 1.35 g/cm³ | ASTM D792 | |||

Mold Shrinkage, Flow(24 hrs) | 0.2 - 0.4 % | ASTM D955 | |||

Mold Shrinkage, XFlow(24 hrs) | 0.2 - 0.4 % | ASTM D955 | |||

Melt Volume Rate, MVR 1.2 kg;MVR at 300 °C 2.16 kg;MVR at 300 °C | 10 cm³/10 min 21 cm³/10 min | ISO 1133 | |||

Water Absorption(24 hrs;23 °C | ) | 0.03 % | ISO 62-1 | ||

Mechanical | Nominal Value | Test Method |

Izod Impact, Notched | ||

23 °C | 140 J/m | ASTM D256 |

-30 °C | 90 J/m | ASTM D256 |

80*10*4;23 °C | 13 kJ/m² | ISO 180/1A |

80*10*4;-30 °C | 9 kJ/m² | ISO 180/1A |

Instrumented Dart Impact, Total Energy(23 °C) | 22 J | ASTM D3763 |

Izod Impact, Unnotched | ||

23 °C | 680 J/m | ASTM D4812 |

80*10*4;23 °C | 41 kJ/m² | ISO 180/1U |

Tensile Modulus | ||

5 mm/min | 6700 MPa | ASTM D638 |

1 mm/min | 6650 MPa | ISO 527 |

Tensile Strain, Break | ||

5 mm/min;Type I | 2.6 % | ASTM D638 |

5 mm/min | 2.6 % | ISO 527 |

Tensile Stress, Break | ||

5 mm/min;Type I | 109 MPa | ASTM D638 |

5 mm/min | 107 MPa | ISO 527 |

Flexural Modulus | ||

1.3 mm/min;50 mm;span | 6050 MPa | ASTM D790 |

2 mm/min | 6150 MPa | ISO 178 |

Flexural Stress, break | ||

1.3 mm/min;50 mm;span | 158 MPa | ASTM D790 |

2 mm/min | 160 MPa | ISO 178 |

Flexural Stress, Yield | ||

1.3 mm/min;50 mm;span | 161 MPa | ASTM D790 |

2 mm/min | 161 MPa | ISO 178 |

Thermal | Nominal Value | Test Method |

UL Recognized ≥ 0.6 mm ≥ 0.5 mm | V-0 V-1 | UL 94 |

Glow Wire Ignition Temperature [GWIT] 2 mm 1 mm 1.6 mm | 850 °C 850 °C 850 °C | IEC 60695-2-13 |

Glow Wire Flammability Index 2 mm 1 mm 1.6 mm | 960 °C 960 °C 960 °C | IEC 60695-2-12 |

Heat Deflection Temperature[HDT], Unannealed 0.45 MPa;3.2 mm 3.2 mm;1.82 MPa | 120 °C 115 °C | ASTM D648 |

CTE, Flow 23°C to 80°C -40 - 40 °C | 2.6e-05 1/°C 2.5e-05 1/°C | ASTM E831 |

CTE, XFlow 23°C to 80°C -40 - 40 °C | 7.5e-05 1/°C 6.3e-05 1/°C | ASTM E831 |

Vicat Softening Temperature Rate B/120 Rate B/50 | 125 °C 122 °C | ISO 306 |

HDT/Af(1.8) | 116 °C | ISO 75/Af |

HDT/Bf(0.45) | 121 °C | ISO 75/Bf |

Relative Temp Index, Elec | 80 °C | UL 746B |

Relative Temp Index, Mechanical with Impact | 80 °C | UL 746B |

Relative Temp Index, Mechanical without Impact | 80 °C | UL 746B |

Electrical | Nominal Value | Test Method |

Surface Resistivity | > 1.0E+16 ohms | ASTM D257 |

Volume Resistivity | > 1.0E+16 ohms ·cm | ASTM D257 |

Comparative Tracking Index, CTI | PLC 3 | UL 746A |

Processing | Nominal Value | |

Back Pressure<Injection> | 0.1 - 0.3 MPa | |

Drying Temperature<Injection> | 110 °C | |

Drying Time<Injection> | 3 - 6 hrs | |

Front, Zone 3 Temperature<Injection> | 280 - 300 °C | |

Maximum Moisture Content<Injection> | 0.02 % | |

Melt Temperature<Injection> | 285 - 310 °C | |

Middle, Zone 2 Temperature<Injection> | 270 - 290 °C | |

Mold Temperature<Injection> | 80 - 110 °C | |

Nozzle Temperature<Injection> | 285 - 305 °C | |

Rear, Zone 1 Temperature<Injection> | 260 - 280 °C | |

Screw Speed <Injection> | 50 - 90 rpm |

Low Warpage

Low Warpage