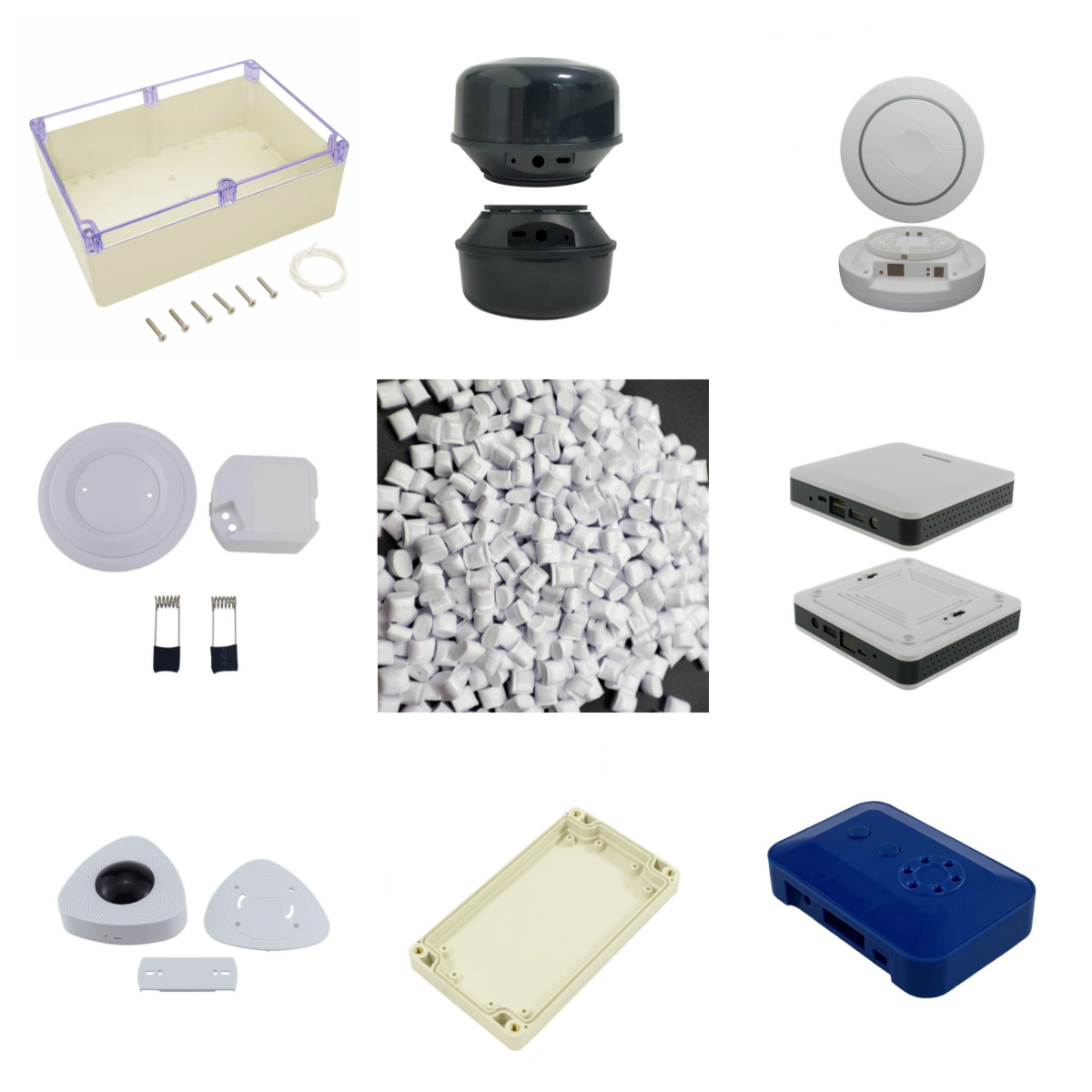

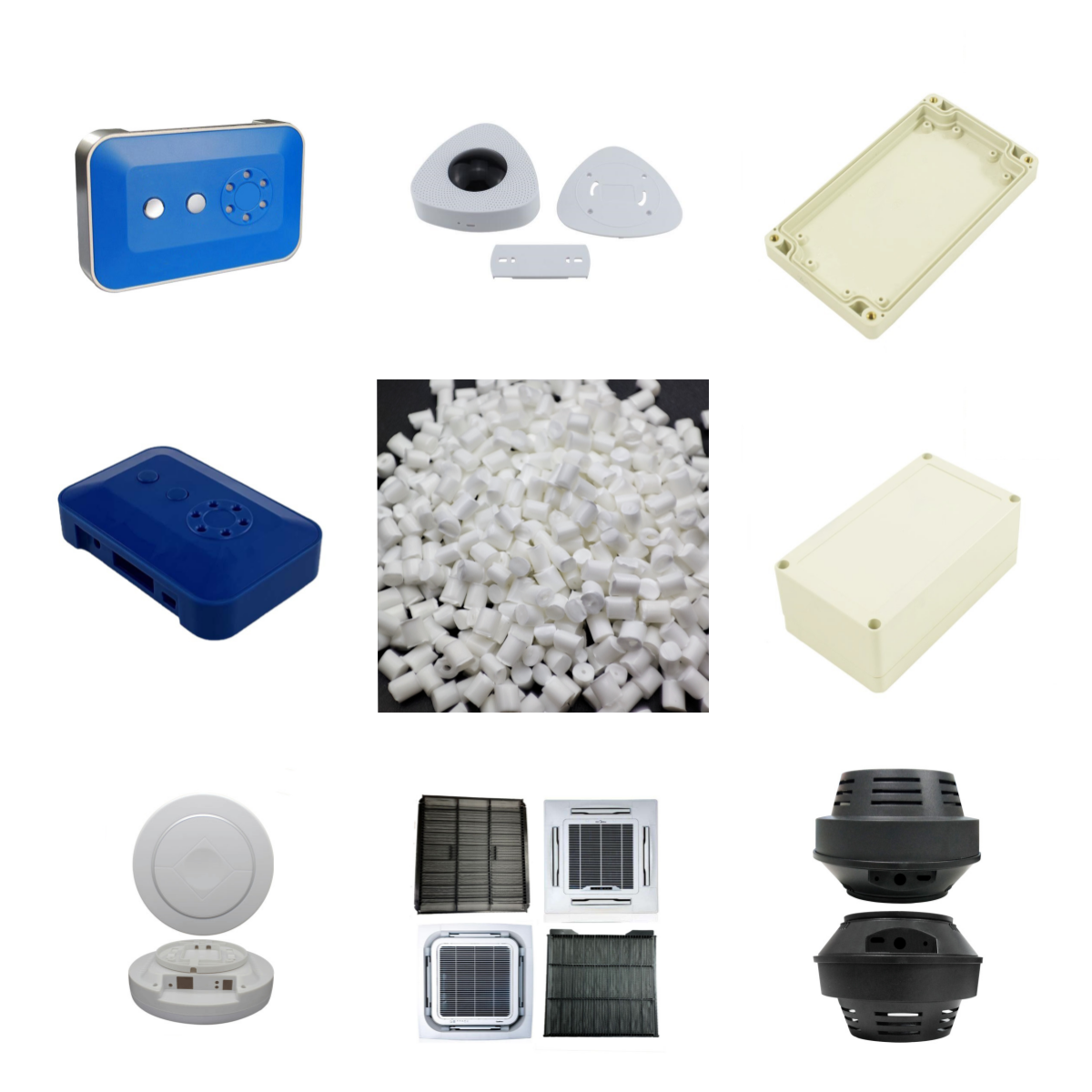

Lighting Application/home Appliance Multi-purpose Polycarbonate Granules PC Particle Raw Material Supplier

Dongguan Forever Co.,Ltd is the manufacture of the China origin cheap UV stablized PC polycarbonate Granules Polymer Resin

LUX2180T-XH is a global-grade injection molding resin specifically developed for producing optical components that demand excellent flow properties, exceptional light transmission, and color stability. This grade is also UV stabilized for enhanced durability.

General | |||

Form |

| ||

Feature |

|

| |

Usage | |||

Physical | Nominal Value | Test Method | |

Density / Specific Gravity | 1.20 g/cm³ | ISO 1183 | |

Melt Volume-Flow Rate, MVR(300 °C;1.2 kg) | 18 cm³/10 min | ISO 1133 | |

Molding Shrinkage, Flow, Tensile Bar | 0.50 - 0.70 % | Internal Method | |

Water Absorption, Saturation(23 °C) | 0.35 % | ISO 62 | |

Water Absorption, Equilibrium(50% RH;23 °C) | 0.15 % | ISO 62 | |

Outdoor Suitability | f1 | UL 746C | |

Ball Indentation Hardness(H 358/30) | 95.0 MPa | ISO 2039-1 | |

Mechanical Nominal Value | Test Method | ||

Tensile Modulus 2250 MPa | ISO 527-2/1 | ||

Tensile Stress, Yield 59.0 MPa | ISO 527-2/50 | ||

Tensile Stress, Break 69.0 MPa | ISO 527-2/50 | ||

Tensile Strain, Yield 6.0 % | ISO 527-2/50 | ||

Tensile Strain, Break 100 % | ISO 527-2/50 | ||

Flexural Modulus(2 mm/min) 2200 MPa | ISO 178 | ||

Flexural Stress, at Yield(2 mm/min) 90.0 MPa | ISO 178 | ||

Taber Abrasion Resistance(1.0e+3 Cycles;1.0e+3 g;CS-1710.0 mg Wheel) | Internal Method | ||

C harpy Notched Impact Strength -30 °C;80 23 °C;80 | 12 kJ/m² 65 kJ/m² | ISO 179 1eA | |

C harpy Unnotched Impact Strength -30 °C;80 23 °C;80 | No Break No Break | ISO 179 1eU | |

Notched Izod Impact Strength -30 °C;80*10*3 mm 23 °C;80*10*3 mm | 15kJ/m² 65kJ/m² | ISO 180/1A | |

Unnotched Izod Impact Strength -30 °C;80*10*3 mm 23 °C;80*10*3 mm | No Break No Break | ISO 180/1U | |

Thermal | Nominal Value | Test Method |

Heat Deflection Temperature, Unannealed 0.45 MPa;120*10*4 mm;4 mm;100 mm;Span 1.8 MPa;120*10*4 mm;4 mm;100 mm;Span | 133 °C 122 °C | ISO 75-2/Be ISO 75-2/Ae |

Vicat Softening Temperature | 140 °C 141 °C | ISO 306/B50 ISO 306/B120 |

Ball Pressure Test(123 - 127 °C) | Pass | IEC 60695-10-2 |

CLTE, Flow(23 - 80 °C) | 7.0E-5 cm/cm/°C | ISO 11359-2 |

Thermal Conductivity | 0.20 W/m-K | ISO 8302 |

RTI Elec | 130 °C | UL 746 |

RTI Imp | 125 °C | UL 746 |

RTI Str | 125 °C | UL 746 |

Flame Rating, Testing by SABIC(0.8 mm) | V-2 | UL 94 |

Glow Wire Flammability Index(1 mm) | 850 °C | IEC 60695-2-12 |

Glow Wire Ignition Temperature [GWIT](1 mm) | > 875 °C | IEC 60695-2-13 |

Oxygen Index | 25 % | ISO 4589-2 |

Electrical | Nominal Value | Test Method |

Surface Resistivity | > 1.0E+15 Ohms | IEC 60093 |

Volume Resistivity | > 1.0E+15 Ohms ·cm | IEC 60093 |

Electric Strength, in Oil(3.2 mm) | 17 kV/mm | IEC 60243-1 |

Relative Permittivity 50 Hz 60 Hz 1.0e+6 Hz | 2.70 2.70 2.70 | IEC 60250 |

Dissipation Factor 50 Hz 60 Hz 1.0e+6 Hz | 1.0E-3 1.0E-3 0.010 | IEC 60250 |

Comparative Tracking Index | 250 V | IEC 60112 |

Optical | Nominal Value | Test Method |

Refractive Index | 1.586 | ISO 489 |

Transmittance | ||

2.5e+3 µm | > 90.0 % | ASTM D1003 |

2.5e+3 µm;420 nm | > 88.0 % | Internal Method |

5.0e+3 µm | > 89.0 % | Internal Method |

Haze(2.5e+3 µm) | < 0.500 % | ASTM D1003 |

Processing | Nominal Value | |

Drying Temperature<Injection> | 120 °C | |

Drying Time<Injection> | 2.0 - 4.0 hr | |

Suggested Max Moisture<Injection> | 0.020 % | |

Hopper Temperature<Injection> | 60 - 80 °C | |

Rear Temperature<Injection> | 260 - 280 °C | |

Middle Temperature<injection> | 270 - 290 °C | |

Front Temperature<Injection> | 280 - 300 °C | |

Nozzle Temperature<Injection> | 270 - 290 °C | |

Processing Temp, Melt<Injection> | 280 - 300 °C | |

Mold Temperature<Injection> | 80 - 100 °C |

Resin Pellets

Resin Pellets