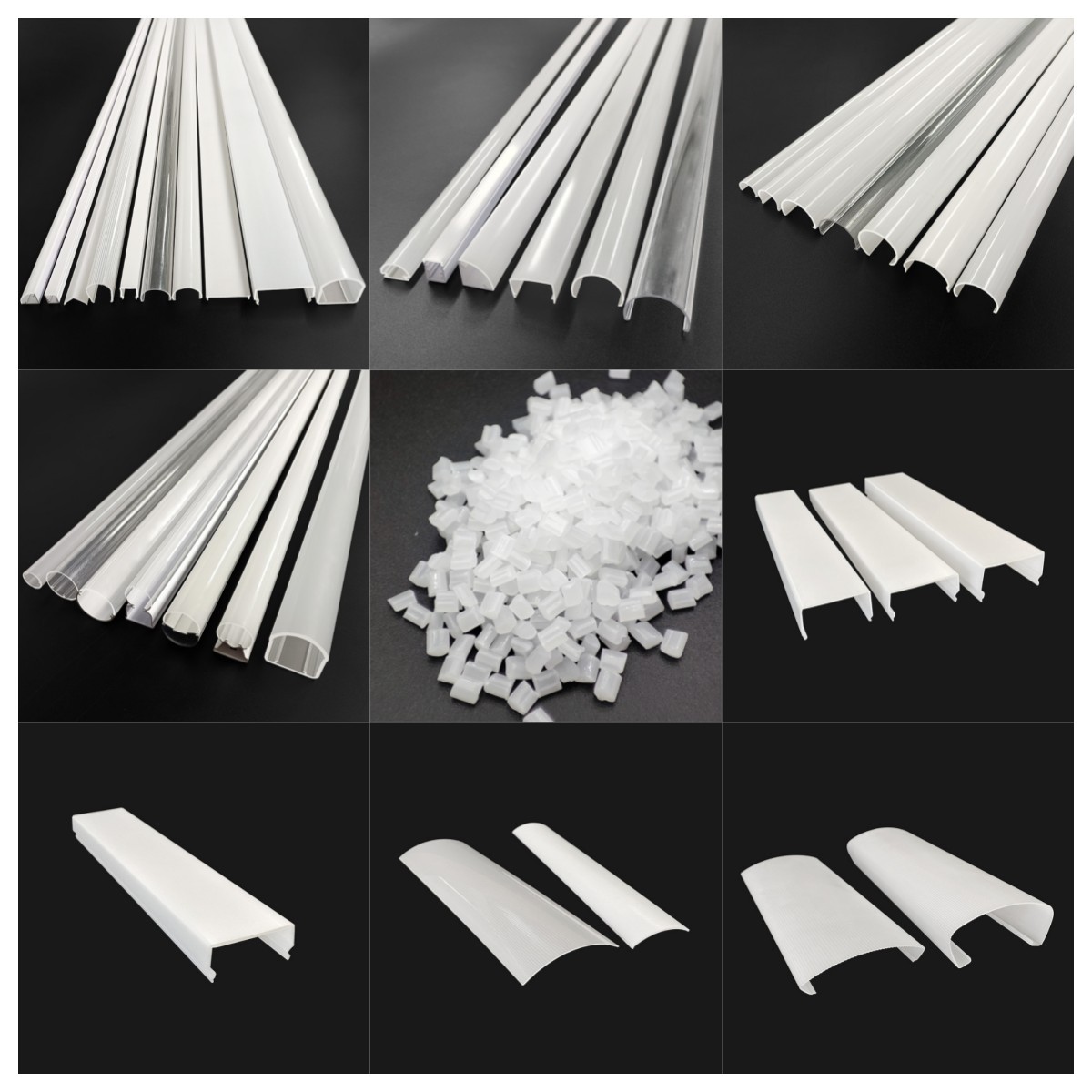

Flame Retardant Injection Extruded Grade PC Plastic Native Particles

Dongguan Forever Co.,Ltd is the manufacture of the China origin cheap UV stablized PC polycarbonate Granules Polymer Resin

DS0036I-XH compound is a Polycarbonate (PC) resin blend with 15% stainless steel fiber content. This grade offers additional benefits such as electrical conductivity, EMI/RFI shielding, high impact resistance, and flame retardancy without the use of brominated or chlorinated materials.

General | ||||

Form | ||||

Filler | ||||

Electrically Conductive | Emi/Rfi Shielding | High Impact | ||

Feature | Non-Brominated & Non-Chlorinated Flame Retardant | Non-Chlorinated | ||

Uses | Consumer Electrical | Packaging | Industria | |

Physical | Nominal Value | Test Method | ||

Mold Shrinkage, Flow(24 hrs) | 0.4 - 0.7 % | ISO 294 | ||

Mold Shrinkage, XFlow(24 hrs) | 0.5 % | ISO 294 | ||

Density / Specific Gravity | 1.29 g/cm³ | ISO 1183 | ||

Mechanical | Nominal Value | Test Method | ||

Izod Impact, Unnotched | ||||

23 °C | 1790 J/m | ASTM D4812 | ||

80*10*4;23 °C | 85 kJ/m² | ISO 180/1U | ||

Izod Impact, Notched | ||||

23 °C | 124 J/m | ASTM D256 | ||

80*10*4;23 °C | 14 kJ/m² | ISO 180/1A | ||

Tensile Stress, Yield | 57 MPa | ISO 527 | ||

Tensile Stress, Break | 55 MPa | ISO 527 | ||

Tensile Strain, Yield | 3.8 % | ISO 527 | ||

Tensile Strain, Break | 4 - 8 % | ISO 527 | ||

Tensile Modulus(1 mm/min) | 2800 MPa | ISO 527 | ||

Flexural Stress | 80 MPa | ISO 178 | ||

Flexural Modulus | 2600 MPa | ISO 178 | ||

Thermal | Nominal Value | Test Method |

CTE, Flow(-40 - 40 °C) | 5.6E-05 1/°C | ISO 11359-2 |

CTE, XFlow(-40 - 40 °C) | 6.7e-05 1/°C | ISO 11359-2 |

HDT/Bf(0.45) | 136 °C | ISO 75/Bf |

HDT/Af(1.8) | 125 °C | ISO 75/Af |

Electrical | Nominal Value | Test Method |

Volume Resistivity | 1.0E+04 ohms ·cm | ASTM D257 |

Surface Resistivity | 100 - 1.0E+04 ohms | ASTM D257 |

Shielding Effectivness @ 3Mm | 40 - 55 dB | SABIC Method |

Processing | Nominal Value | |

Drying Temperature<Injection> | 120 °C | |

Drying Time<Injection> | 4 hrs | |

Maximum Moisture Content<Injection> | 0.02 % | |

Melt Temperature<Injection> | 305 - 325 °C | |

Front, Zone 3 Temperature<Injection> | 320 - 330 °C | |

Middle, Zone 2 Temperature<Injection> | 310 - 320 °C | |

Rear, Zone 1 Temperature<Injection> | 295 - 305 °C | |

Mold Temperature<Injection> | 95 - 120 °C | |

Back Pressure<Injection> | 0.2 - 0.3 MPa | |

Screw Speed <Injection> | 30 - 60 rpm |

Resin Pellets

Resin Pellets