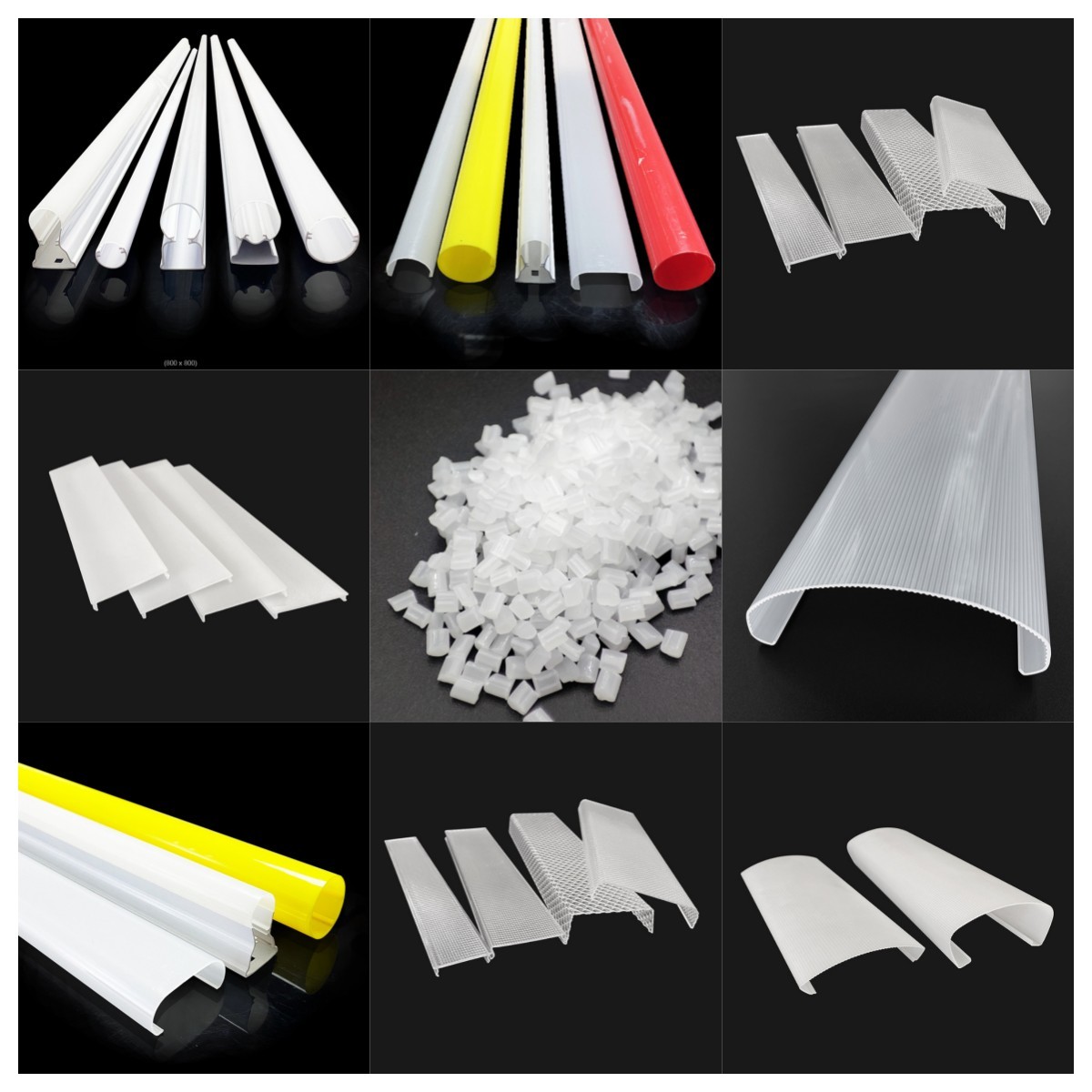

Chemical Resistance And High Toughness Resin Plastic Material PC Raw Material

Dongguan Forever Co.,Ltd is the manufacture of the China origin cheap UV stablized PC polycarbonate Granules Polymer Resin

DF0041VI-XH compound is a specialized Polycarbonate (PC) resin with a 20% glass fiber content. This grade offers several enhanced features such as improved plating surface and mechanical performance, making it suitable for Laser Direct Structuring (LDS) applications. Additionally, it is non-brominated and non-chlorinated, providing flame retardant properties without these harmful additives. The wide processing window allows for ease of manufacturing and versatility in various applications.

General | |||

Form | Resin Pellets | ||

Filler | 20% glass fiber | ||

Feature | Good Hardness Lds | Non-Brominated & Non- Chlorinated Flame Retardant Structural | Non-Chlorinated Circuit Solution |

Usage | Consumer Building and Construction | Electrical | |

Physical | Nominal Value | Test Method | |

Melt Flow Rate[MFR] 300 °C;2.16 kgf 300 °C;1.2 kgf | 17 g/10min 10 g/10min | ASTM D1238 | |

Density / Specific Gravity | 1.4 g/cm³ | ASTM D792 | |

Mechanical | Nominal Value | Test Method |

Izod Impact, Notched | ||

23 °C | 80 J/m | ASTM D256 |

80*10*4;23 °C | 8 kJ/m² | ISO 180/1A |

Izod Impact, Unnotched | ||

23 °C | 450 J/m | ASTM D4812 |

80*10*4;23 °C | 26 kJ/m² | ISO 180/1U |

C harpy Impact, V-Notched(23 °C;Edgew;80*10*4;sp =62 mm 0) | 8 kJ/m² | ISO 179 1eA |

C harpy Impact, Unnotched(23 °C;Edgew;80*10*4;sp =62 mm 0) | 30 kJ/m² | ISO 179 1eU |

Tensile Stress, Break | ||

5 mm/min;Type I | 85 MPa | ASTM D638 |

5 mm/min | 86 MPa | ISO 527 |

Tensile Strain, Break | ||

5 mm/min;Type I | 2.5 % | ASTM D638 |

5 mm/min | 2.5 % | ISO 527 |

Tensile Modulus | ||

5 mm/min | 7000 MPa | ASTM D638 |

1 mm/min | 6900 MPa | ISO 527 |

Flexural Modulus | ||

1.3 mm/min;50 mm;span | 6000 MPa | ASTM D790 |

2 mm/min | 6400 MPa | ISO 178 |

Flexural Strength | ||

1.3 mm/min;50 mm;span | 125 MPa | ASTM D790 |

2 mm/min | 130 MPa | ISO 178 |

Thermal | Nominal Value | Test Method |

Heat Deflection Temperature[HDT], Unannealed 0.45 MPa;3.2 mm 3.2 mm;1.82 MPa | 124 °C 118 °C | ASTM D648 |

Electrical | Nominal Value | Test Method |

Processing | Nominal Value | |

Drying Temperature<Injection> | 110 - 120 °C | |

Drying Time<Injection> | 3 - 4 hrs | |

Melt Temperature<Injection> | 290 - 310 °C | |

Nozzle Temperature<Injection> | 285 - 310 °C | |

Front, Zone 3 Temperature<Injection> | 285 - 310 °C | |

Middle, Zone 2 Temperature<Injection> | 285 - 310 °C | |

Rear, Zone 1 Temperature<Injection> | 285 - 310 °C | |

Mold Temperature<Injection> | 100 - 130 °C | |

Back Pressure<Injection> | 0.1 - 0.3 MPa | |

Screw Speed <Injection> | 50 - 150 rpm |

Laser Direct Structuring

Laser Direct Structuring