Thermal Conductive Plastics Raw Materials Polycarbonate PC Price for Led Grow Light

Dongguan Forever Co.,Ltd is the manufacture of the China origin cheap UV stablized PC polycarbonate Granules Polymer Resin

The specific heat capacity of PC 300 TC-I-15-XH Generally refers to the heat required when the temperature of plastic molded products rises by 1°C. Specific heat capacity is the same as thermal conductivity and is the reference data for studying the temperature rise of target products in product design.

The continuous operating temperature of 300 TC-I-15-XH reflects the heat resistance of plastic molded products. Generally divided into physical heat resistance and chemical heat resistance. The former refers to the performance of maintaining the shape of the product at a specified heating temperature; the latter represents the thermal stability of molecular bonds in plastic molding materials.

General | |||

Form | |||

Feature | Thermally

| ||

Physical | Nominal Value | Test Method | |

Density / Specific Gravity | 2.45 g/cm³ | ASTM D792 | |

Mechanical | Nominal Value | Test Method | |

Tensile Strength, Break | 34.5 MPa | ASTM D638 | |

Elongation at Break | < = 1.0 % | ASTM D638 | |

Tensile Modulus | 1.03E+4 MPa | ASTM D638 | |

Flexural Strength | 55.2 MPa | ASTM D790 | |

Flexural Modulus | 1.03E+4 MPa | ASTM D790 | |

Izod Impact, Notched(Thickness; 3.2 mm) | 26.7 J/m | ASTM D256 | |

Izod Impact, Unnotched(Thickness; 3.2 mm) | 80.1 J/m | ASTM D4812 | |

Thermal | Nominal Value | Test Method | |

Thermal conductivity through plane(through-plane) | 0.751 W/m-K | ASTM E1530 | |

Deflection Temperature(Pressure; 1.8 MPa) | 116 °C | ASTM D648 | |

Electrical | Nominal Value | Test Method | |

Surface Resistivity per Square | > = 1.00e+12 Ohms | ASTM D257 | |

Processing | Nominal Value | ||

Melt Temperature | 288 - 316 °C | ||

Mold Temperature | 82.2 - 121 °C | ||

Drying Temperature(Time 4 hr) | 121 °C | ||

Moisture Content | 0.020 % | ||

Dew Point | -28.9 °C | ||

Injection Pressure | 68.9 - 103 MPa | ||

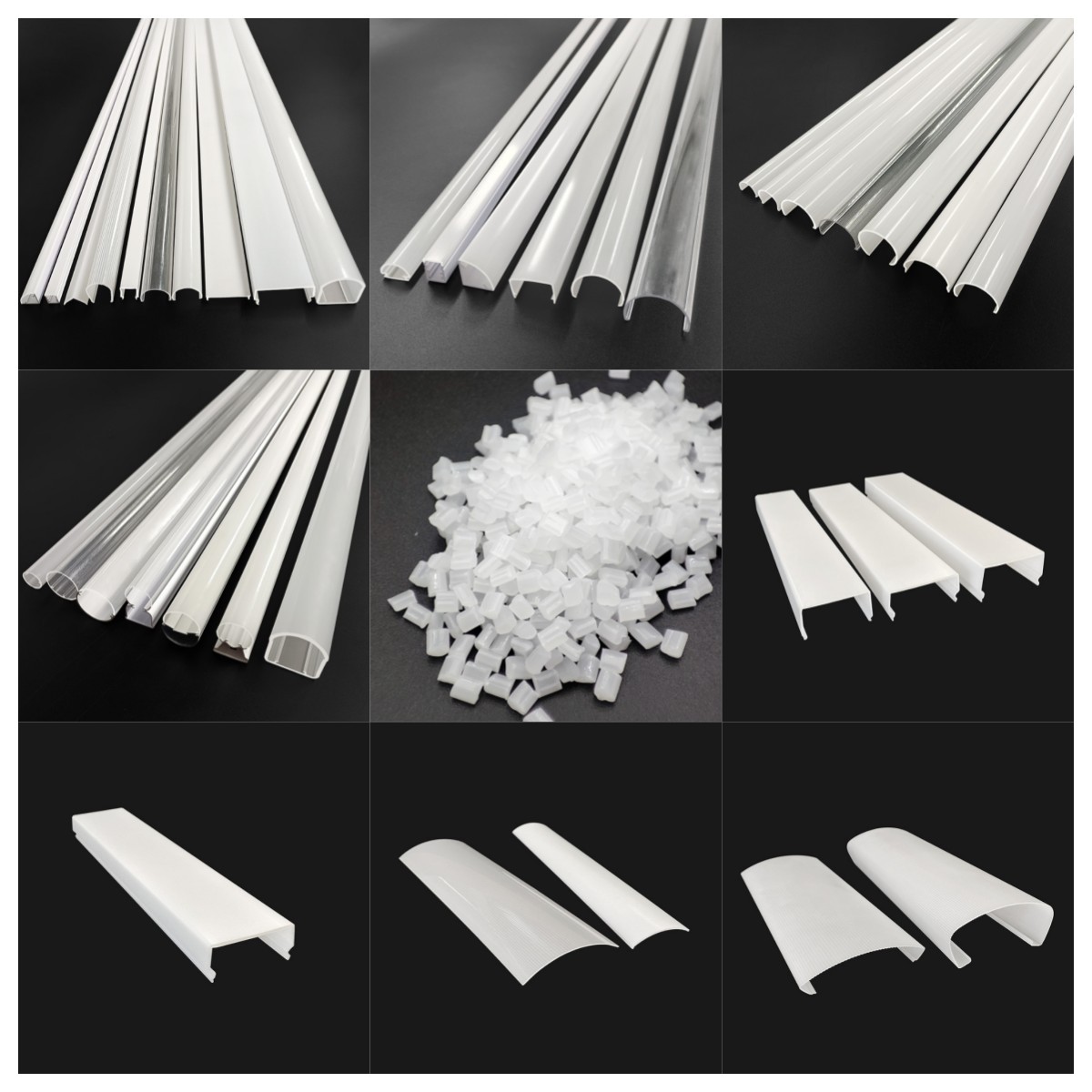

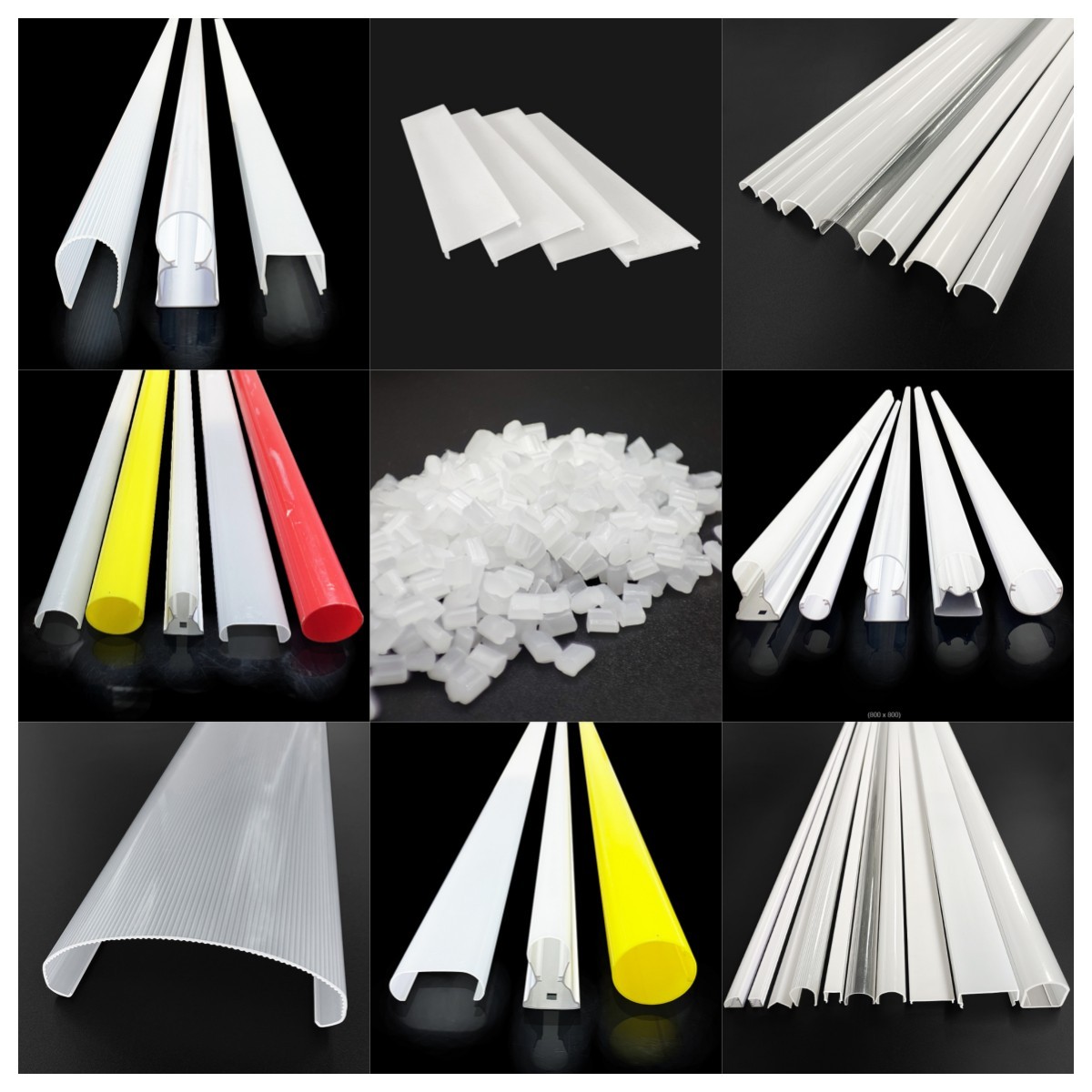

Resin Pellets

Resin Pellets