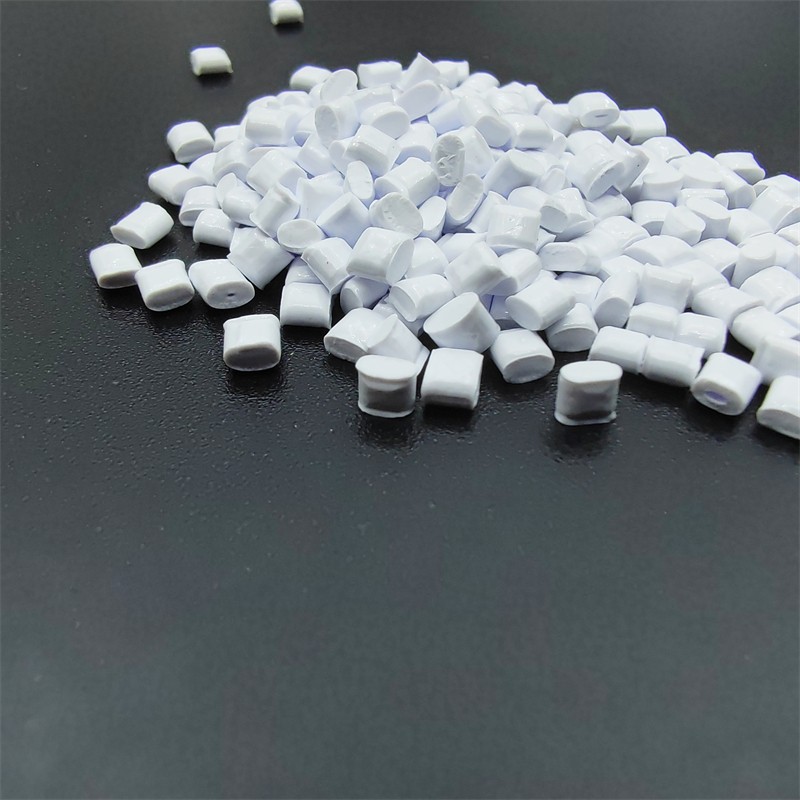

Sabic Lexan 503RS

Product Description |

a medium viscosity, glass reinforced, flame retardant grade UV stabilized grade pc polycarbonate . |

General |

Form |

Filler |

Feature |

Uses |

Physical Nominal Value Test Method |

Density / Specific Gravity 1.26 g/cm³ ISO 1183 |

Moisture Absorption(50% RH;23 °C) 0.130 % ISO 62 |

Water Absorption at Saturation 0.31 % ISO 62 |

Linear Mold Shrinkage, Flow(Tensile Bar) 0.2 - 0.6 % |

Melt Volume Rate, MVR(1.2 kg;300 °C) 8.0 cm³/10 min ISO 1133 |

Ball Indentation Hardness(H 358/30) 115 MPa ISO 2039-1 |

Mechanical | Nominal Value | Test Method |

Tensile Strength, Break | 65.0 MPa | ISO 527 |

Tensile Strength, Yield | 70.0 MPa | ISO 527 |

Elongation at Break | 4.0 % | ISO 527 |

Elongation at Yield | 3.0 % | ISO 527 |

Tensile Modulus | 3900 MPa | ISO 527 |

Flexural Yield Strength | 120 MPa | ISO 178 |

Flexural Modulus | 4000 MPa | ISO 178 |

Izod Impact, Notched, ISO Temperature; 23 °C;80x10x3 mm Temperature; -30 °C;80x10x3 mm |

9.00 kJ/m² 8.00 kJ/m² | ISO 180/1A |

Izod Impact, Unnotched, ISO Temperature; 23 °C;80x10x3 mm Temperature; -30 °C;80x10x3 mm |

No Break 100 kJ/m² | ISO 180/1eU |

C harpy Impact Unnotched Temperature; 23 °C Temperature; -30 °C |

No Break No Break | ISO 179 1eU |

C harpy Impact, Notched Temperature; 23 °C Temperature; -30 °C |

9 kJ/m² 8 kJ/m² | ISO 179 1eA |

Thermal | Nominal Value | Test Method |

CTE, Flow(23 - 80 °C) | 40.0 µm/m-°C | ISO 11359-2 |

Thermal Conductivity | 0.210 W/m-K | ISO 8302 |

Deflection Temperature Pressure; 0.46 MPa;Edgew;120*10*4;sp =100mm 0 Pressure; 1.8 MPa;Edgew;120*10*4;sp =100mm 0 |

142 °C 137 °C |

ISO 75/Be ISO 75/Ae |

Vicat Softening Point Rate B/50 Rate B/120 |

144 °C 147 °C | ISO 306 |

Flammability, UL94(Thickness; 1.5 mm) | V-0 | UL 94 |

Oxygen Index | 36 % | ISO 4589 |

Glow Wire Test(Thicknessl; 1 mm) | 960 °C | IEC 60695-2-12 |

Electrical | Nominal Value |

Previous:Trinseo EMERGE 8701-8

Next:High Modulus Flame Retardance UV Stabilized PC Polycarbonate

Inquiry |