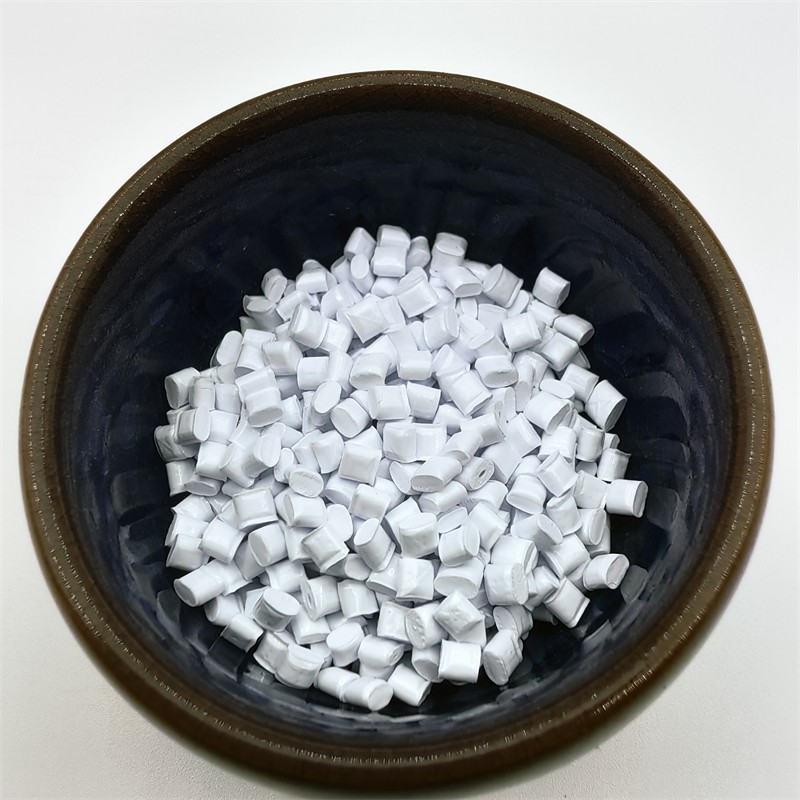

Trinseo EMERGE 8701-8

General | |||

Form |

| ||

Filler |

| ||

Feature |

|

|

|

Uses |

|

| |

Physical | Nominal Value | Test Method | |

Density / Specific Gravity | 1.28 g/cm³ | ASTM D792 | |

Melt Flow(300 °C;1.2 kg) | 8.0 g/10min | ASTM D1238 | |

Molding Shrinkage, Flow | |||

0.35 - 0.50 % | ASTM D955 | ||

0.40 - 0.60 % | ISO 294-4 | ||

Molding Shrinkage, Across | Flow | 0.40 - 0.55 % | ASTM D955 |

Mechanical | Nominal Value | Test Method |

Tensile Modulus | ||

1 mm/min | 4000 MPa 4000 MPa | ASTM D638 ISO 527-1/1 |

Tensile Strength, Yield | ||

5 mm/min | 65.0 MPa 65.0 MPa | ASTM D638 ISO 527-2/5 |

Tensile Strength, Break | ||

5 mm/min | 65.0 MPa 45.0 MPa | ASTM D638 ISO 527-2/5 |

Elongation at Break | ||

5 mm/min | 4.0 % 9.0 % | ASTM D638 ISO 527-2/5 |

Flexural Modulus | ||

1.3 mm/min | 3800 MPa | ASTM D790 |

2 mm/min | 3800 MPa | ISO 178 |

Flexural Strength | ||

1.3 mm/min | 120 MPa | ASTM D790 |

2 mm/min | 105 MPa | ISO 178 |

C harpy Notched Impact Strength(23 °C) | 6.0 kJ/m² | ISO 179/1eA |

Izod Impact, Notched(23 °C;4 mm) | 9.0 kJ/m² | ISO 180/1A |

Thermal | Nominal Value | Test Method |

Deflection Temperature Under Load, Unannealed 0.45 MPa 1.8 MPa 0.45 MPa 1.8 MPa |

138 °C 129 °C 141 °C 133 °C |

ASTM D648 ASTM D648 ISO 75-2/B ISO 75-2/A |

Deflection Temperature Under Load, Annealed(1.8 MPa) | 139 °C | ISO 75-2/A |

Vicat Softening Temperature | 145 °C | ISO 306/B50 |

Ball Indentation Temperature | > 130 °C | IEC 60335-1 |

CLTE, Flow | 1.5E-5 cm/cm/°C | ISO 11359-2 |

Flame

Previous:Covestro Makrolon 9415

Next:Sabic Lexan 503RS

|