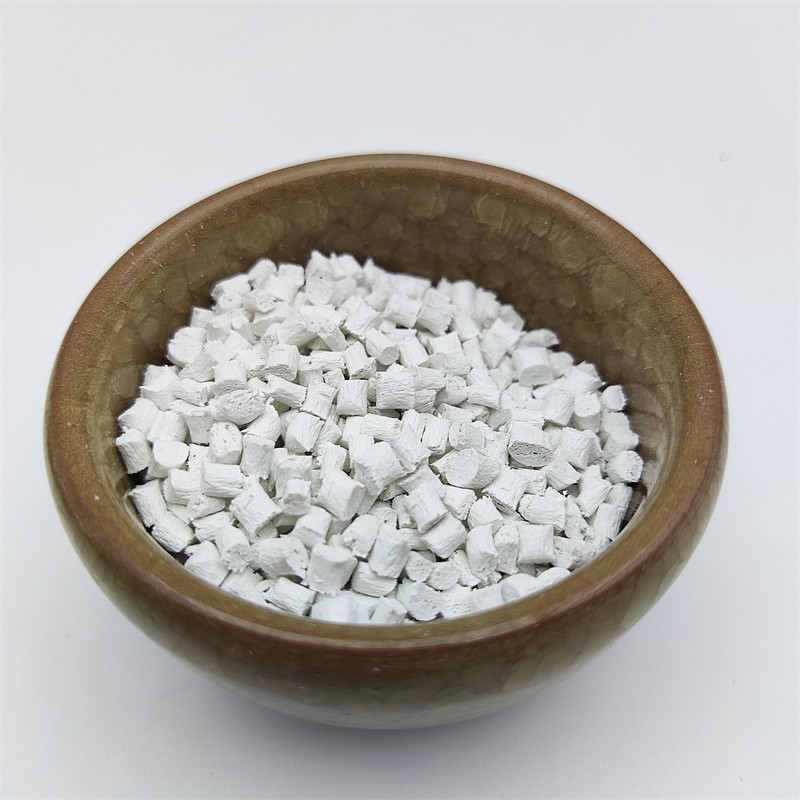

Multipurpose Engineering Plastic Alloy PC/ABS High Impact Resistance Compounds Granules

Dongguan Forever Co.,Ltd is the manufacture of the china origin cheap UV stablized PC polycarbonate Granules Polymer Resin

The comprehensive performance of WP-1089-XH is good, and it also has the advantages of high impact strength, chemical stability and good electrical performance.WP-1089-XH also has high impact resistance, high heat resistance, flame retardant, enhanced, transparent and other levels.

General | ||

Form | ||

Physical | Nominal Value | Test Method |

Density / Specific Gravity, Natural | 1.13 g/cm³ | ASTM D792;ISO 1183 |

Melt Mass-Flow Rate, MFR | ASTM D1238;ISO 1133 | |

250 °C;10 kg | 47 g/10min | |

260 °C;5 kg | 27 g/10min | |

Molding Shrinkage, Flow | ||

3.2 mm | 0.40 - 0.70 % | ASTM D955 |

2 mm | 0.40 - 0.70 % | ISO 294-4 |

Molding Shrinkage, Across Flow | ||

3.2 mm | 0.40 - 0.70 % | ASTM D955 |

2 mm | 0.40 - 0.70 % | ISO 294-4 |

Rockwell Hardness, R-Scale | 113 | ASTM D785;ISO 2039-2 |

Mechanical | Nominal Value | Test Method |

Tensile Modulus | ||

50 mm/min | 2100 MPa 2100 MPa | ASTM D638 ISO 527-2/50 |

Tensile Strength, Yield | ||

50 mm/min | 53.0 MPa 52.0 MPa | ASTM D638 ISO 527-2/50 |

Tensile Strength, Break | ||

50 mm/min | 44.0 MPa 45.0 MPa | ASTM D638 ISO 527-2/50 |

Tensile Elongation, Break | ||

50 mm/min | 80 % 60 % | ASTM D638 ISO 527-2/50 |

Flexural Modulus | ||

2.8 mm/min | 2100 MPa | ASTM D790 |

2 mm/min | 2200 MPa | ISO 178 |

Flexural Strength | ||

2.8 mm/min | 76.0 MPa | ASTM D790 |

2 mm/min | 80.0 MPa | ISO 178 |

C harpy Notched Impact Strength(23 °C;4 mm) | 51 kJ/m² | ISO 179 1eA |

Notched Izod Impact | ||

-30 °C;3.18 mm | 390 J/m | ASTM D256 |

-30 °C;6.35 mm | 200 J/m | ASTM D256 |

23 °C;3.18 mm | 590 J/m | ASTM D256 |

23 °C;6.35 mm | 420 J/m | ASTM D256 |

-30 °C;4 mm | 32 kJ/m² | ISO 180/1A |

23 °C;4 mm | 46 KJ/m² | ISO 180/1A |

Thermal | Nominal Value | Test Method |

Deflection Temperature Under Load, Unannealed 0.45 MPa;6.4 mm 1.8 MPa;6.4 mm | 130 °C 110 °C | ASTM D648 |

Deflection Temperature Under Load, Annealed | ||

0.45 MPa;4 mm | 126 °C | ISO 75-2/B |

1.8 MPa;4 mm | 107 °C | ISO 75-2/A |

Vicat Softening Temperature | 126 °C | ISO 306/B50 |

CLTE, Flow(40 - 100 °C) | 8.1E-5 cm/cm/°C | ASTM E831;ISO 11359-2 |

CLTE, Transverse(40 - 100 °C) | 8.3E-5 cm/cm/°C | ASTM E831;ISO 11359-2 |

Processing | Nominal Value | |

Drying Temperature, Desiccant Dryer<Injection> | 90 - 100 °C | |

Drying Temperature, Hot Air Dryer<Injection> | 90 - 100 °C | |

Drying Time, Desiccant Dryer<Injection> | 2.0 - 4.0 hr | |

Drying Time, Hot Air Dryer<Injection> | 2.0 - 4.0 hr | |

Suggested Max Moisture<Injection> | 0.020 % | |

Rear Temperature<Injection> | 210 - 230 °C | |

Middle Temperature<injection> | 230 - 250 °C | |

Front Temperature<Injection> | 250 - 265 °C | |

Nozzle Temperature<Injection> | 250 - 280 °C | |

Mold Temperature<Injection> | 60 - 90 °C | |

Injection Pressure<Injection> | 58.8 MPa | |

Back Pressure<Injection> | 0.490 - 2.45 MPa | |

Screw Speed <Injection> | 50 - 80 rpm | |

Hot Runner Temperature<Injection> | 250 - 280 °C |

Resin Pellets

Resin Pellets