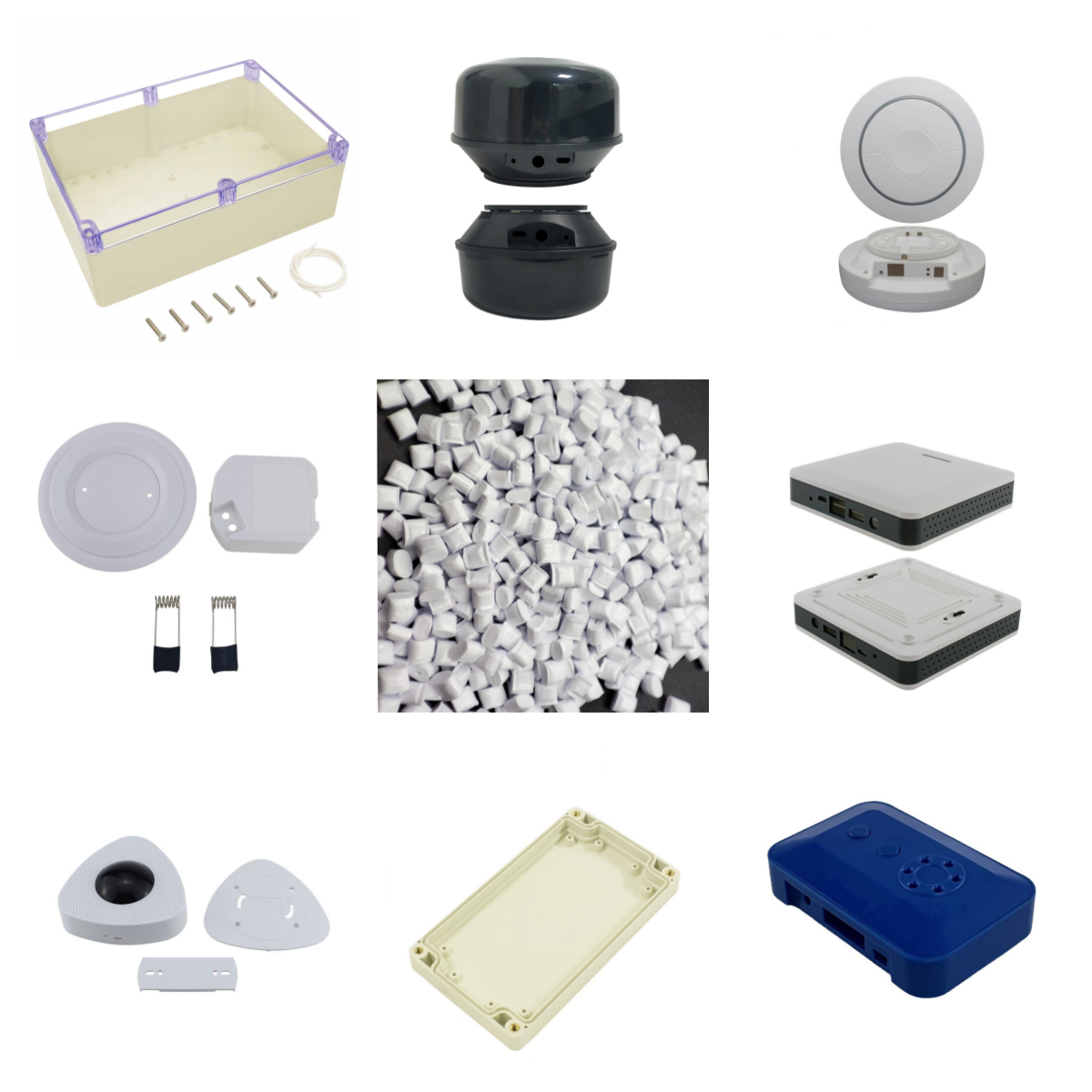

Polyamide 6 Price Heat Resistant PA6 Raw Material for Industrial Electronic Applications

Dongguan Forever Co.,Ltd is the manufacture of the China origin cheap UV stablized PC polycarbonate Granules Polymer Resin

A 218 V15 BK 21N-XH is a heat-stabilized polyamide 6 material with 15% glass fiber reinforcement,

designed specifically for injection molding.

This grade showcases a remarkable balance of thermal and mechanical properties,

making it highly versatile and reliable for various applications.

General | |||

Form | |||

Filler | |||

Feature | |||

Usage |

|

| |

Physical Nominal Value Test Method | |||

Density / Specific Gravity 1.24 g/cm³ ISO 1183 | |||

Water Absorption(24 hr, 23°C) 1.1 % ISO 62 | |||

Molding shrinkage, parallel(72 hr, 23°C, 50% RH) 0.5 % | ISO 294-4, ISO 2577 | ||

Molding shrinkage, normal(72 hr, 23°C, 50% RH) 1.4 % | ISO 294-4, ISO 2577 | ||

Mechanical | Nominal Value | Test Method |

Tensile Modulus 1 mm/min;dry 1 mm/min;conditioned | 6200 MPa 4300 MPa | ISO 527-1/-2 |

Stress at break dry conditioned | 125 MPa 90 MPa | ISO 527-1/-2 |

Strain at break dry conditioned | 3 % 8 % | ISO 527-1/-2 |

Flexural Modulus 2 mm/min;dry 2 mm/min;conditioned | 5300 MPa 3500 MPa | ISO 178 |

Flexural Strength(2 mm/min;conditioned) | 115 MPa | ISO 178 |

C harpy Impact Strength, Unnotched 23 °C;dry 23 °C;conditioned | 40 kJ/m² 65 kJ/m² | ISO 179 1eU |

C harpy Notched Impact Strength 23 °C;dry 23 °C;conditioned | 5 kJ/m² 6.5 kJ/m² | ISO 179 1eA |

Izod impact strength, Notched 23 °C;dry 23 °C;conditioned | 40 kJ/m² 65 kJ/m² | ISO 180/1U |

Notched Izod Impact Strength 23 °C;dry 23 °C;conditioned | 5 kJ/m² 10 kJ/m² | ISO 180/1A |

Thermal | Nominal Value | Test Method |

Melting Temperature(10°C/min) | 263 °C | ISO 11357-1 |

Temp. of deflection under load(1.8 MPa) | 245 °C | ISO 75 |

Flammability(3 mm) | HB | UL 94 |

Oxygen Index | 24 % |

Electrical | Nominal Value | Test Method |

Volume Resistivity | 1E+11 ohms ·cm | IEC 62631-3-1 |

Surface Resistivity | 6E+015 Ohms | IEC 62631-3-1 |

Comparative Tracking Index(Solution A) | 400 V | IEC 60112 |

Dielectric Strength(1 mm) | 31 kV/mm | IEC 60243-1 |

Processing | Nominal Value | |

Drying Temperature(除湿干燥机) | 80 °C | |

Drying Time(除湿干燥机) | 2 - 4 h | |

Suggested Max Moisture | 0.2 % | |

Rear Temperature | 270 - 280 °C | |

Middle Temperature | 275 - 285 °C | |

Front Temperature | 280 - 290 °C | |

Blow Molding Mold Temperature | 70 - 100 °C |

Resin Pellets

Resin Pellets