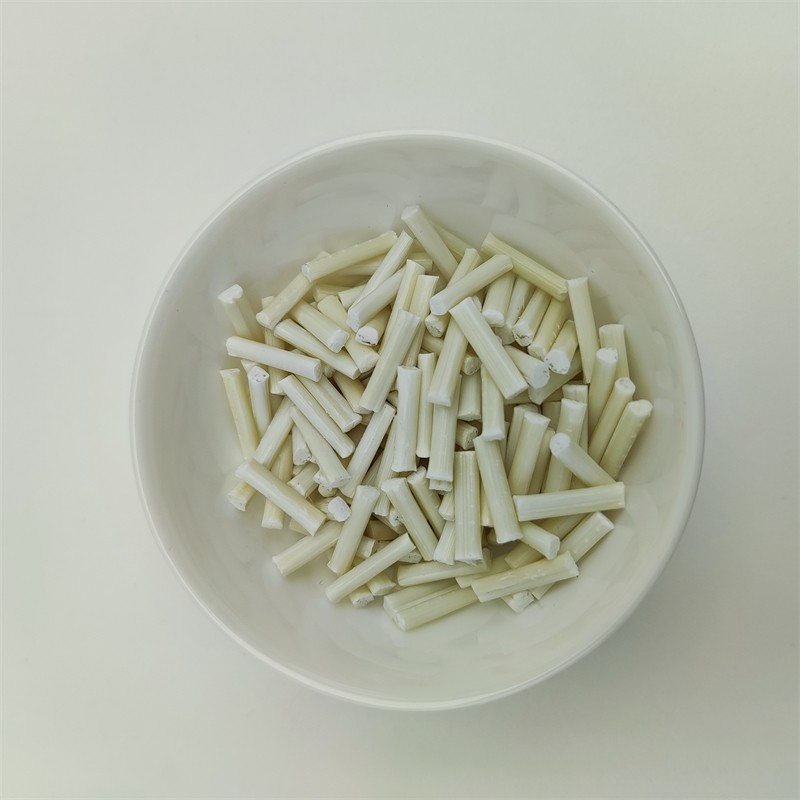

Low Viscosity High Impact And Ductile PC/ABS Resin Raw Material Pellets

Dongguan Forever Co.,Ltd is the manufacture of the China origin cheap UV stablized PC polycarbonate Granules Polymer Resin

MC8002-XH polycarbonate/acrylonitrile butadiene styrene (PC/ABS) blend is an injectable, high flow, non chlorinated/brominated flame retardant grade product. This grade has improved chemical resistance and is a good candidate material for thin-walled applications.

General | |||

Form | |||

Feature | |||

Usage

| Automotive Under The Hood Automotive Interior Appliances |

Automotive Lighting Applications |

Automotive Lighting |

Physical Nominal Value Test Method | |||

Density / Specific Gravity 1.14 g/cm³ ASTM D792 | |||

Melt Mass-Flow Rate, MFR(260 °C;5 kg) 9.0 g/10min ASTM D1238 | |||

Molding Shrinkage, Flow(3.2 mm) 0.50 - 0.70 % Internal Method | |||

Water Absorption(24 hr) 0.10 % ASTM D570 | |||

Water Absorption, Equilibrium(23 °C) 0.40 % ASTM D570 | |||

Mechanical Nominal Value Test Method | |||

Tensile Modulus(50 mm/min) 2200 MPa ASTM D638 | |||

Tensile Strength, Yield(50 mm/min;Type I) 56.0 MPa ASTM D638 | |||

Tensile Elongation, Yield(50 mm/min;Type I) 5.0 % ASTM D638 | |||

Tensile Elongation, Break(50 mm/min;Type I) 150 % ASTM D638 | |||

Flexural Modulus(1.3 mm/min;50 mm;Span) 2340 MPa ASTM D790 | |||

Flexural Strength, Yield(1.3 mm/min;50 mm;Span) 86.0 MPa ASTM D790 | |||

Notched Izod Impact ASTM D256 | |||

-30 °C 530 J/m | |||

23 °C 640 J/m | |||

Instrumented Dart Impact, Total Energy ASTM D3763 | |||

-30 °C 54.0 J | |||

23 °C 61.0 J | |||

Thermal | Nominal Value | Test Method |

Deflection Temperature Under Load, Unannealed 0.45 MPa;3.2 mm 1.8 MPa;3.2 mm 1.8 MPa;6.4 mm | 123 °C 107 °C 110 °C | ASTM D648 |

CLTE, Flow(-40 - 40 °C) | 7.2E-5 cm/cm/°C | ASTM E831 |

Thermal Conductivity | 0.20 W/m-K | ASTM C177 |

Processing | Nominal Value | |

Drying Temperature<Injection> | 105 - 110 °C | |

Drying Time<Injection> | 3.0 - 4.0 hr | |

Suggested Max Moisture<Injection> | 0.040 % | |

Suggested Shot Size<Injection> | 30 - 80 % | |

Rear Temperature<Injection> | 250 - 290 °C | |

Middle Temperature<injection> | 255 - 295 °C | |

Front Temperature<Injection> | 260 - 300 °C | |

Nozzle Temperature<Injection> | 275 - 300 °C | |

Processing Temp, Melt<Injection> | 275 - 300 °C | |

Mold Temperature<Injection> | 60 - 90 °C | |

Back Pressure<Injection> | 0.300 - 0.700 MPa | |

Screw Speed <Injection> | 40 - 70 rpm | |

Vent Depth <Injection> | 0.038 - 0.076 mm | |

Drying Time, Cumulative<Injection> | 8 hrs |

Resin Pellets

Resin Pellets