High Impact PC/ABS Alloy Plastics Raw Material Resin Used for Plating And Painting Applications

Dongguan Forever Co.,Ltd is the manufacture of the China origin cheap UV stablized PC polycarbonate Granules Polymer Resin

MC1300-XH type PC/ABS has excellent flow and impact properties for electroplating and coating applications.

General | ||||||

Form | ||||||

Feature | Ductile |

| ||||

| ||||||

| Lawn And Garden Equipment | Pharmaceuticals | ||||

Usage Aerospace | Automotive | Sporting Goods | ||||

Automotive Exterior | Automotive Interior | Constraction | ||||

Rail | Outdoor | |||||

Physical | Nominal Value | Test Method | ||||

Density / Specific Gravity | 1.10 g/cm³ | ASTM D792 | ||||

Melt Mass-Flow Rate, MFR(260 °C;5 kg) | 14 g/10min | ASTM D1238 | ||||

Molding Shrinkage, Across Flow(3.2 mm) | 0.50 - 0.70 % | Internal Method | ||||

Molding Shrinkage, Flow(3.2 mm) | 0.50 - 0.80 % | Internal Method | ||||

Water Absorption(24 hr) | 0.10 % | ASTM D570 | ||||

Mechanical | Nominal Value | Test Method | ||||

Tensile Modulus(50 mm/min) | 2130 MPa | ASTM D638 | ||||

Tensile Strength, Yield(50 mm/min;Type I) | 50.0 MPa | ASTM D638 | ||||

Tensile Strength, Break(50 mm/min;Type I) | 44.0 MPa | ASTM D638 | ||||

Tensile Elongation, Yield(50 mm/min;Type I) | 8.6 % | ASTM D638 | ||||

Tensile Elongation, Break(50 mm/min;Type I) | 150 % | ASTM D638 | ||||

Flexural Modulus(1.3 mm/min;50 mm;Span) | 2060 MPa | ASTM D790 | ||||

Flexural Strength, Yield(1.3 mm/min;50 mm;Span) | 72.0 MPa | ASTM D790 | ||||

Notched Izod Impact | ASTM D256 | |||||

-30 °C | 430 J/m | |||||

23 °C | 530 J/m | |||||

Instrumented Dart Impact, Total Energy | ASTM D3763 | |||||

-30 °C | 33.0 J | |||||

23 °C | 40.0 J | |||||

Thermal | Nominal Value | Test Method |

Deflection Temperature Under Load, Unannealed 0.45 MPa;3.2 mm 1.8 MPa;3.2 mm | 115 °C 98.0 °C | ASTM D648 |

Vicat Softening Temperature(50 °C/h;50 N;Rate A;Loading 2) | 111 °C | ASTM D1525 |

CLTE, Flow(-40 - 40 °C) | 7.2E-5 cm/cm/°C | ASTM E831 |

CLTE, Transverse(-40 - 40 °C) | 9.0E-5 cm/cm/°C | ASTM E831 |

Thermal Conductivity | 0.20 W/m-K | ASTM C177 |

Processing | Nominal Value | |

Drying Temperature<Injection> | 100 - 105 °C | |

Drying Time<Injection> | 3.0 - 4.0 hr | |

Suggested Max Moisture<Injection> | 0.020 % | |

Suggested Shot Size<Injection> | 30 - 80 % | |

Rear Temperature<Injection> | 250 - 280 °C | |

Middle Temperature<injection> | 255 - 290 °C | |

Front Temperature<Injection> | 255 - 290 °C | |

Nozzle Temperature<Injection> | 260 - 290 °C | |

Processing Temp, Melt<Injection> | 260 - 290 °C | |

Mold Temperature<Injection> | 75 - 100 °C | |

Back Pressure<Injection> | 0.300 - 0.700 MPa | |

Screw Speed <Injection> | 40 - 70 rpm | |

Vent Depth <Injection> | 0.038 - 0.076 mm | |

Drying Time, Cumulative<Injection> | 8 hrs |

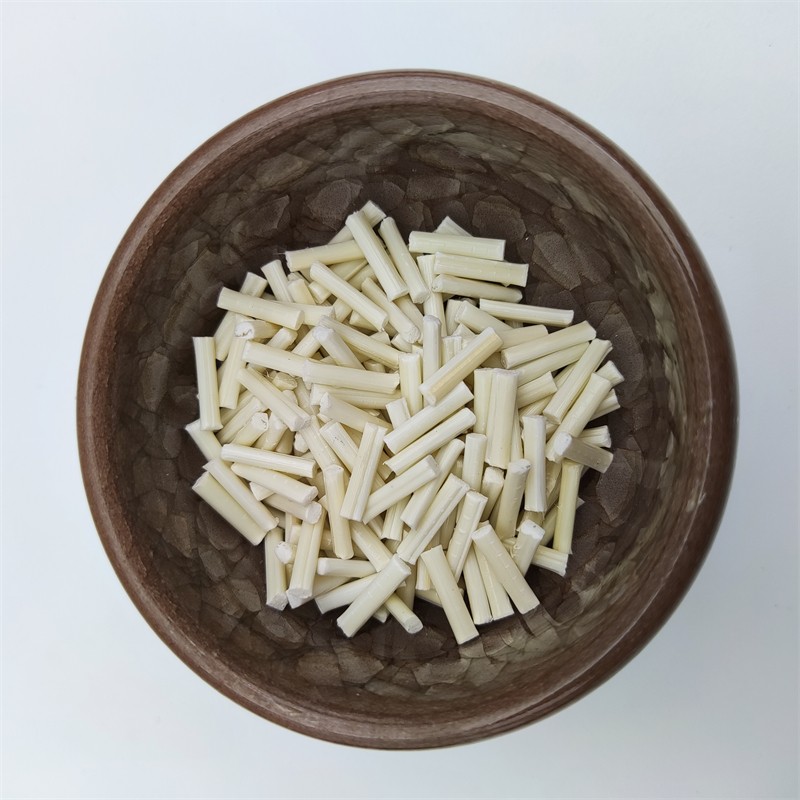

Resin Pellets

Resin Pellets