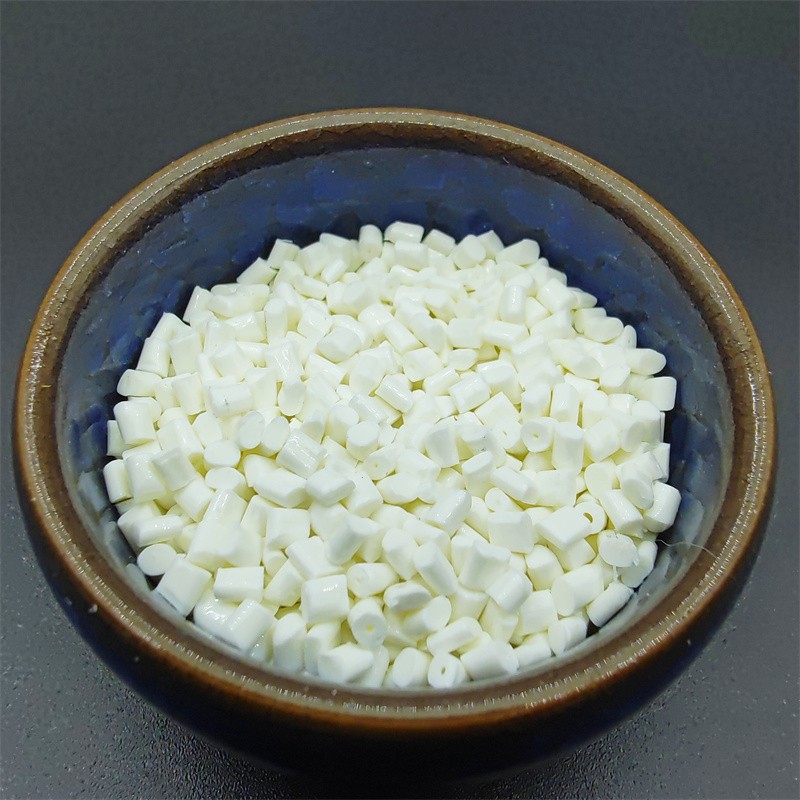

High Impact Resistance Raw Material PA 6 Granules Virgin Polycarbonate Resin

B3ZG6 BK30564-XH is a high-performance PA6 grade for injection molding, featuring impact modification,

pigmented black color, and a 30% glass fiber reinforcement.

This grade is specifically designed for industrial applications requiring excellent impact strength and rigidity.

Typical applications for B3ZG6 BK30564-XH include automotive airbag housings and half-shells used in suitcases.

General | ||||

Form | Resin Pellets | |||

Filler | 30 % Glass Fiber | |||

Usage |

|

| ||

Physical | Nominal Value | Test Method | ||

Density / Specific Gravity | 1.33 g/cm³ | ISO 1183 | ||

Melt Volume-Flow Rate, MVR(275 °C;5 kg) | 25 cm³/10 min | ISO 1133 | ||

Water Absorption, Saturation(23 °C) | 6.2 % | ISO 62 | ||

Water Absorption, Equilibrium(50% RH;23 °C) | 2.0 % | ISO 62 | ||

Mechanical | Nominal Value | Test Method | ||

Tensile Modulus(23 °C) | 8800 MPa | ISO 527-2 | ||

Tensile Stress, Break(23 °C) | 150 MPa | ISO 527-2 | ||

Tensile Strain, Break(23 °C) | 3.2 % | ISO 527-2 | ||

Flexural Modulus(23 °C) | 7900 MPa | ISO 178 | ||

C harpy Notched Impact Strength | ISO 179 | |||

-30 °C | 8.0 kJ/m² | |||

23 °C | 15 kJ/m² | |||

Notched Izod Impact Strength | ISO 180 | |||

-30 °C | 8.0 kJ/m² | |||

23 °C | 16 kJ/m² | |||

Thermal | Nominal Value | Test Method | ||

Heat Deflection Temperature, Unannealed(1.8 MPa) | 205 °C | ISO 75-2/A | ||

Melting Temperature, DSC | 220 °C | ISO 3146 | ||

Processing | Nominal Value |

Drying Temperature<Injection> | 80 °C |

Drying Time<Injection> | 2.0 - 4.0 hr |

Suggested Max Moisture<Injection> | 0.080 % |

Rear Temperature<Injection> | 245 - 275 °C |

Middle Temperature<injection> | 260 - 285 °C |

Front Temperature<Injection> | 270 - 295 °C |

Nozzle Temperature<Injection> | 270 - 295 °C |

Processing Temp, Melt<Injection> | 270 - 295 °C |

Mold Temperature<Injection> | 80 - 95 °C |

Injection Pressure<Injection> | 3.50 - 12.5 MPa |

Injection Rate<Injection> | Fast |

Industrial Applications

Industrial Applications