PC OQ3820XH

Dongguan Forever Co.,Ltd is the manufacture of the china origin cheap UV stablized PC polycarbonate Granules Polymer Resin

OQ3820-XH has outstanding impact resistance, good creep resistance and dimensional stability, heat resistance, low water absorption, non-toxic, and excellent dielectric properties. The reason why OQ3820-XH has a large market capacity is due to its comprehensive and balanced performance.

General |

Form |

Feature |

Usage |

Physical Nominal Value Test Method |

Density / Specific Gravity 1.19 g/cm³ ASTM D792 1.20 g/cm³ ISO 1183 |

Melt Mass-Flow Rate, MFR(300 °C;1.2 kg) 7.4 g/10min ASTM D1238 |

Melt Volume-Flow Rate, MVR(300 °C;1.2 kg) 6.00 cm³/10 min ISO 1133 |

Molding Shrinkage, Across Flow(3.2 mm) 0.50 - 0.70 % Internal Method |

Molding Shrinkage, Flow(3.2 mm) 0.60 - 0.80 % Internal Method |

Water Absorption, Saturation(23 °C) 0.32 % ISO 62 |

Water Absorption, Equilibrium(50% RH;23 °C) 0.15 % ISO 62 |

Mechanical Nominal Value Test Method |

Tensile Modulus |

50 mm/min 2270 MPa ASTM D638 |

2400 MPa ISO 527-2/1 |

Tensile Strength, Yield |

50 mm/min;Type I 62.0 MPa ASTM D638 |

61.0 MPa ISO 527-2/50 |

Tensile Strength, Break |

50 mm/min;Type I 72.0 MPa ASTM D638 |

71.0 MPa ISO 527-2/50 |

Tensile Elongation, Yield |

50 mm/min;Type I 6.3 % ASTM D638 |

6.0 % ISO 527-2/50 |

Tensile Elongation, Break |

50 mm/min;Type I 130 % ASTM D638 |

140 % ISO 527-2/50 |

Flexural Modulus 1.3 mm/min;50 mm;Span 2 mm/min | 2410 MPa 2200 MPa | ASTM D790 ISO 178 |

Flexural Stress, at Yield(2 mm/min) | 94.0 MPa | ISO 178 |

Flexural Stress, Yield(1.3 mm/min;50 mm;Span) | 93.0 MPa | ASTM D790 |

C harpy Notched Impact Strength -30 °C;80 23 °C;80 | 15 kJ/m² 75 kJ/m² | ISO 179 1eA |

C harpy Unnotched Impact Strength -30 °C;80 23 °C;80 | No Break No Break | ISO 179 1eU |

Notched Izod Impact -30 °C 23 °C -30 °C;80*10*3 mm 23 °C;80*10*3 mm | 14 J/m 920 J/m 12 kJ/m² 70 kJ/m² | ASTM D256 ASTM D256 ISO 180/1A ISO 180/1A |

Unnotched Izod Impact Strength -30 °C;80*10*3 mm 23 °C;80*10*3 mm | No Break No Break | ISO 180/1U |

Instrumented Dart Impact, Total Energy(23 °C) | 85.0 J | ASTM D3763 |

Thermal | Nominal Value | Test Method |

Deflection Temperature Under Load, Unannealed | ||

0.45 MPa;3.2 mm | 139 °C | ASTM D648 |

1.8 MPa;3.2 mm | 129 °C | ASTM D648 |

1.8 MPa;120*10*4 mm;4 mm;100 mm;Span | 126 °C | ISO 75-2/Ae |

Vicat Softening Temperature | ||

50 °C/h;50 N;Rate A;Loading 2 | 150 °C 143 °C 144 °C | ASTM D1525 ISO 306/B50 ISO 306/B120 |

Ball Pressure Test(73 - 77 °C) | Pass | IEC 60695-10-2 |

CLTE, Flow | ||

-40 - 40 °C | 7.7E-5 cm/cm/°C | ASTM E831 |

-40 - 40 °C | 7.6E-5 cm/cm/°C | ISO 11359-2 |

CLTE, Transverse | ||

-40 - 40 °C | 7.7E-5 cm/cm/°C | ASTM E831 |

-40 °C | 7.9E-5 cm/cm/°C | ISO 11359-2 |

Processing | Nominal Value | |

Drying Temperature<Injection> | 120 °C | |

Drying Time<Injection> | 3.0 - 4.0 hr | |

Suggested Max Moisture<Injection> | 0.020 % | |

Suggested Shot Size<Injection> | 40 - 60 % | |

Rear Temperature<Injection> | 290 - 310 °C | |

Middle Temperature<injection> | 300 - 320 °C | |

Front Temperature<Injection> | 310 - 330 °C | |

Nozzle Temperature<Injection> | 305 - 325 °C | |

Processing Temp, Melt<Injection> | 310 - 330 °C | |

Mold Temperature<Injection> | 80 - 115 °C | |

Back Pressure<Injection> | 0.300 - 0.700 MPa | |

Screw Speed <Injection> | 40 - 70 rpm | |

Vent Depth <Injection> | 0.025 - 0.076 mm | |

Drying Time, Cumulative<Injection> | 48 hrs |

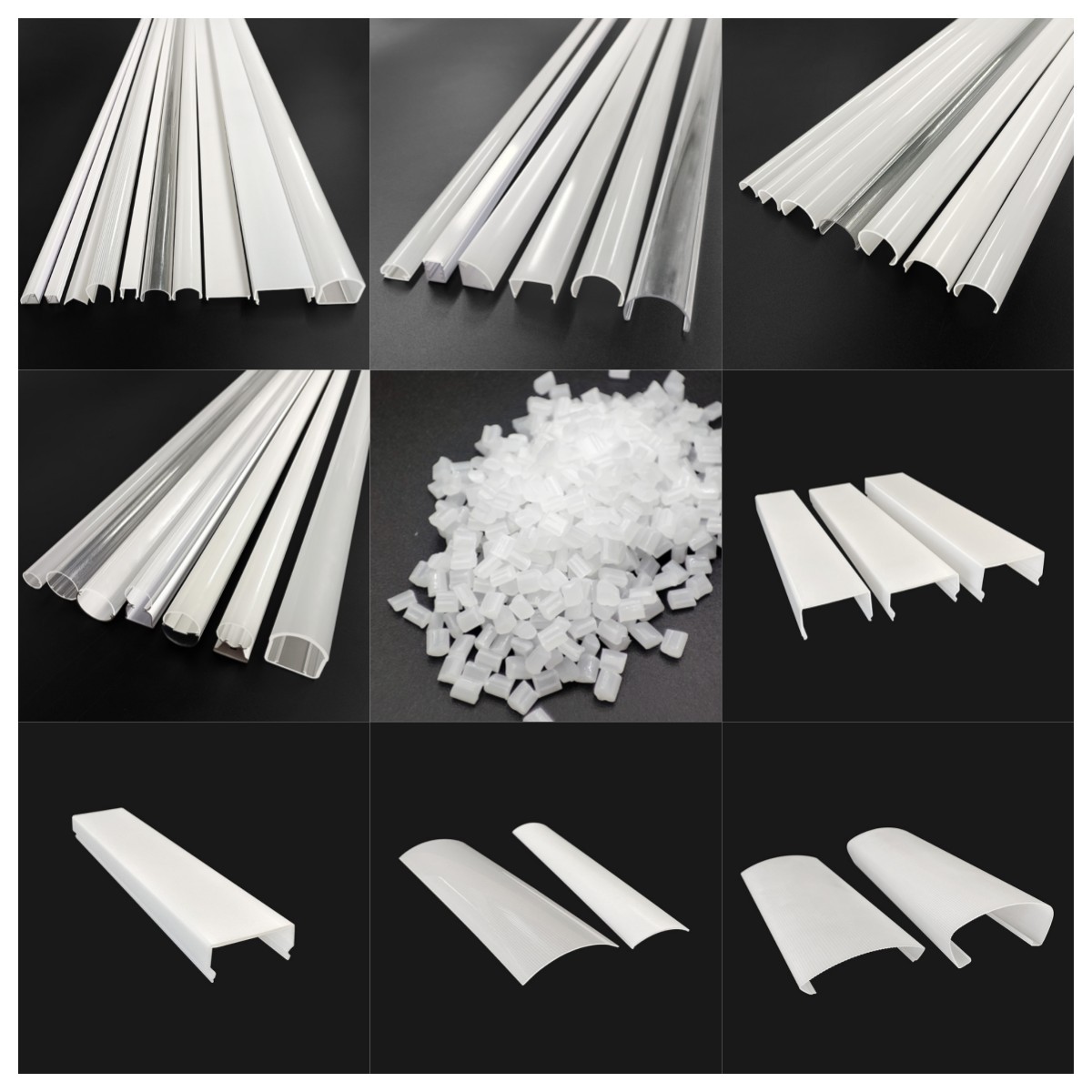

Resin Pellets

Resin Pellets