News

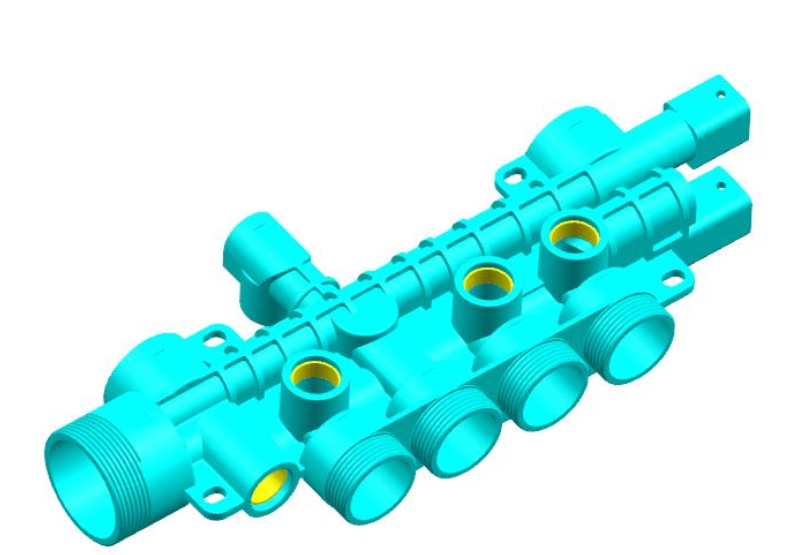

Easy Process Production Plastics Raw Materials For Complex-Shaped Water Diversion Valve Components

3. Excellent Processability: FOREVER Adapts to Diverse Production Needs

Optimized specifically for injection molding, FOREVER's high-performance water-contact material fully considers

the actual needs of the production end, can easily form various complex-shaped water diversion valve components,

and simplifies the production process for cooperative manufacturers. It has a reasonable processing temperature range,

with specific parameters as follows, helping manufacturers improve production efficiency and reduce costs.

Processing Parameters | Temperature (℃) |

Barrel Temperature - Nozzle | 270 |

Barrel Temperature - Front | 265 |

Barrel Temperature - Middle (First Section) | 265 |

Barrel Temperature - Middle (Second Section) | 260 |

Barrel Temperature - Rear | 250 |

Mold Temperature - Stationary Platen (Oil Temperature) | 80 |

Mold Temperature - Moving Platen (Oil Temperature) | 80 |

During the molding process, the material exhibits good fluidity and smooth demolding,

which can effectively reduce production scrap rate, help FOREVER's cooperative manufacturers

improve production efficiency, control processing costs, and achieve dual improvements in quality and efficiency.

In the future, FOREVER will continue to deepen the R&D of new materials,

help the high-quality development of the bathroom industry with more competitive products,

and bring safer, more durable, and higher-quality water experiences to global users.

If any questions, please visit www.forever-plastics.com email to [email protected]

Related News

- FOREVER XLPE 700E-JY: High Performance C 2026-03-21

- Advantages of XLPE Material 2026-03-14

- FOREVER: Cross-Linked Polyethylene (XLPE 2026-03-07

- FOREVER Solutions for Floor Heating Wate 2026-02-18

- FOREVER Water-Contact Material Pass US N 2026-02-11

Categories

Contact us

Forever Co., Ltd.

Contact:Elaine

Mobile:+86 135 39 444 950

Email:[email protected]

Add:No. 85, private road, qiwutang Industrial Zone, Wanjiang District, Dongguan City, Guangdong Province, China