News

Application of Light Diffusion PC In LED Lighting Field

What is Light Diffusion PC

Light-diffusing PC is made by adding a light-diffusing agent to the PC resin. The light-diffusing agent is spherical and evenly dispersed in the PC resin to form an island structure. Due to the different refractive indexes of the PC resin and the light-diffusing agent, the light will resemble a mirror on the surface of the light-diffusing agent. Reflection, after multiple reflections, achieves the light diffusion effect. The amount of light diffusing agent added, particle size and distribution, and refractive index determine the optical properties of the material. Indicators for evaluating the optical properties of light diffusion materials include total light transmittance, haze, and dispersion. The dispersion refers to the angle at which the relative transmittance is 50%. How to achieve high transmittance and high haze of astigmatic materials , this is a difficult point. The light from the fluorescent lamp is irradiated around, and the light from the back is reflected and returned to the front. If the light from the front exceeds the critical angle, it will be reflected. Such light will go through various reflection processes and return to the front. Other light from the diffusion plate will undergo some refraction. After arriving inside the diffusion plate, it meets the diffusing agent and undergoes multiple reflections and astigmatism, maintaining a certain brightness on the surface during this process.

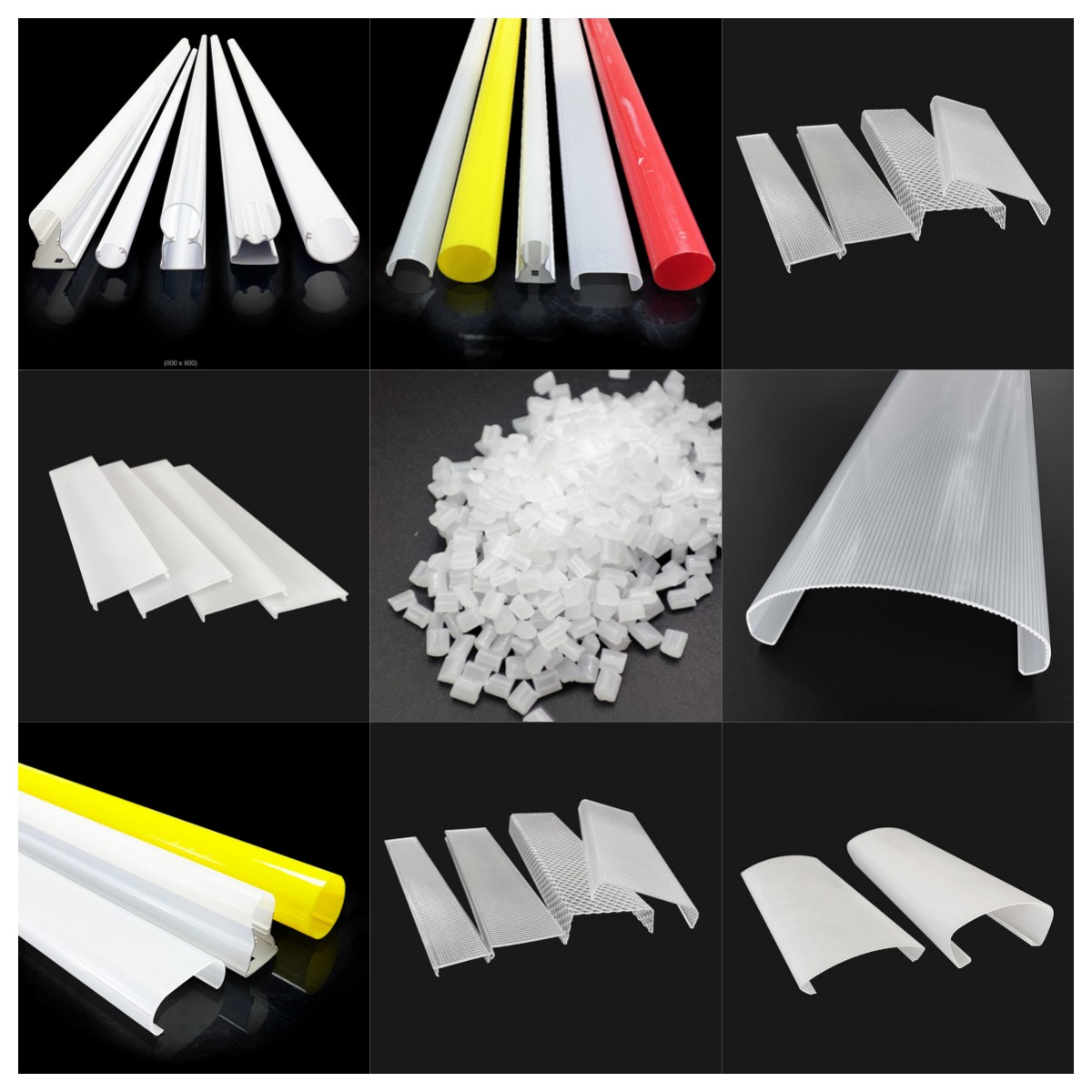

The diffusion rate of Light Diffusion PC can reach 99%, it is evenly dispersed without crystal points, the light transmittance can reach 86-93%, and the brightness is more than 2 times that of traditional lampshades. Mainly divided into injection molding grade, extrusion grade, blow molding grade, film grade and frosted grade.

Features of light diffusion plastic

1. Optical grade PC raw material with high light transmittance, high diffusion, no glare and no light and shadow.

2. Aging resistance, good flame retardancy, and good UV resistance.

3. It can be extruded or injection molded, easy to use and low loss.

4. The light source has excellent concealment and no light spots.

5. Has high impact strength.

6. Special light-diffusion PC plastic for LED lighting shades suitable for LED bulbs, lamp tubes, light-transmitting panels, casings, etc.

Light Diffusion PC is achieved by adding a light diffusing agent to the PC resin. The light is mirror-likely reflected on the surface of the light diffusing agent. After multiple reflections, the light diffusion effect is achieved. The diffusion rate of Light Diffusion PC can reach 99%, it is evenly dispersed without crystal points, the light transmittance can reach 86-93%, and the brightness is more than 2 times that of traditional lampshades. Commonly used in LED bulbs, LED fluorescent lamps, LED digital tubes, LED tunnel lights, LED street lights, LED ceiling lights, etc.

Related News

- Polycarbonate vs. Acrylic: Choosing the 2025-09-10

- The Engineer's Guide to Plastic Material 2025-09-05

- The Ultimate Guide to Different Types of 2025-08-30

- Comparison of Plastics Materials for In 2025-08-28

- What plastics raw materials is best choi 2025-08-21

Categories

Contact us

Dongguan Forever Co., Ltd.

Contact:Elaine

Mobile:+86 135 39 444 950

Email:[email protected]

Add:No. 85, private road, qiwutang Industrial Zone, Wanjiang District, Dongguan City, Guangdong Province, China